LD77MH and QD77MS Simple Motion Modules

The LD77MH and QD77MS simple motion modules offer the flexibility to include or add motion to the L series PLC. A variety of controls including positioning control, speed control, torque control, cam control and synchronous control can be achieved with simple parameter settings and a sequence program. The LD77MH and QD77MS modules are capable of 2 axes and 16 axes of control and add the functionality and convenience of using the MR-J3-B Safety amplifiers with Mitsubishi’s 50Mbps high-speed optical communication Servo System Control Network (SSCNETIII).

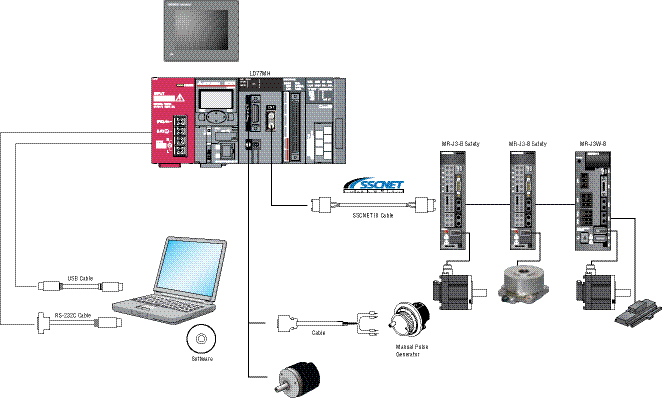

System Configuration

LD77MH Parts List

|

Model Number |

Description |

Stocked Items |

|

LD77MH4 |

4 Axis Motion Controller for L Series PLC |

S |

|

LD77MH16 |

16 Axis Motion Controller for L Series PLC |

S |

|

GX-WORKS2-C1 |

PLC and Motion Programming Software |

S |

|

MR-CONFIGURATOR2 |

Communication Software for MR-J3-B Safety Amplifiers |

S |

|

MR-HDP01 |

Optional Manual Pulse Generator |

S |

|

Cables and Accessories | ||

|

MR-ECN1 |

External I/O Signal Connector. |

S |

|

LD77DOCBL-2M |

Differential Output Type Cable for External I/O - 2 Meter |

S |

|

LD77DOCBL-5M |

Differential Output Type Cable for External I/O - 5 Meter |

S |

|

LD77DOCBL-10M |

Differential Output Type Cable for External I/O - 10 Meter |

S |

|

LD77DOCBL-20M |

Differential Output Type Cable for External I/O - 20 Meter |

- |

|

LD77DOCBL-30M |

Differential Output Type Cable for External I/O - 30 Meter |

- |

|

LD77OCCBL-2M |

Voltage Output/Open Collector Cable for External I/O - 2 Meter |

S |

|

LD77OCCBL-5M |

Voltage Output/Open Collector Cable for External I/O - 5 Meter |

S |

|

LD77OCCBL-10M |

Voltage Output/Open Collector Cable for External I/O - 10 Meter |

S |

|

MR-J3BUS015M |

0.15 meter SSCNET III (plastic) cable from LD77MH to MR-J3-B Safety Amplifier |

S |

|

MR-J3BUS03M |

0.3 meter SSCNET III (plastic) cable from LD77MH to MR-J3-B Safety Amplifier |

S |

|

MR-J3BUS05M |

0.5 meter SSCNET III (plastic) cable fromLD77MH to MR-J3-B Safety Amplifier |

S |

|

MR-J3BUS1M |

1 meter SSCNET III (plastic) cable from LD77MH to MR-J3-B Safety Amplifier |

S |

|

MR-J3BUS3M |

3 meter SSCNET III (plastic) cable from LD77MH to MR-J3-B Safety Amplifier |

S |

|

MR-J3BUS5M-A |

5 meter SSCNET III (plastic) cable from LD77MH to MR-J3-B Safety Amplifier |

S |

|

MR-J3BUS10M-A |

10 meter SSCNET III (plastic) cable from LD77MH to MR-J3-B Safety Amplifier |

S |

|

MR-J3BUS20M-A |

20 meter SSCNET III (plastic) cable from LD77MH to MR-J3-B Safety Amplifier |

S |

|

MR-J3BUS30M-B |

30 meter SSCNET III (glass) cable from LD77MH to MR-J3-B Safety Amplifier |

S |

|

MR-J3BUS40M-B |

40 meter SSCNET III (glass) cable from LD77MH to MR-J3-B Safety Amplifier |

- |

|

MR-J3BUS50M-B |

50 meter SSCNET III (glass) cable from LD77MH to MR-J3-B Safety Amplifier |

- |

|

MR-TBNATBL05M |

0.5M cable used to make a connection to the LD77MH4 and LD77MH16 |

- |

|

MR-TBNATBL1M |

1M cable used to make a connection to the LD77MH4 and LD77MH16 |

- |

|

MR-TB26A |

Junction terminal block |

S |

|

Manuals | ||

|

IB(NA)0300172 |

LD77MH Simple Motion Module User’s Manual |

MEAU.com |

|

IB(NA)0300163 |

MR Configurator2 (SW1DNC-MRC2-E) Installation Guide |

MEAU.com |

LD77MH Performance Specifications

|

Model Number |

LD77MH4 |

LD77MH16 | |

|

Stocked Status |

S |

S | |

|

Number of Control Axes |

4 |

16 | |

|

Operation Cycle (ms) |

0.88 |

0.88/1.77 | |

|

Control System |

PTP (Point To Point) control, path control (both linear and arc can be set), speed control, speed-position switching control, position-speed switching control, Speed-torque control | ||

|

Control Unit |

mm, inch, degree, PLS | ||

|

Positioning Data |

600 data/axis. (Can be set with GX Works2 or sequence program.) | ||

|

Backup |

Parameters, positioning data, and block start data can be saved on flash ROM (battery-less backup) | ||

|

Positioning System |

PTP control: Incremental system/absolute system Speed-position switching control: Incremental system/absolute system (*1) Position-speed switching control: Incremental system Path control: Incremental system/absolute system | ||

|

Applicable Connector for External Input Signal |

LD77MHIOCON | ||

|

SSCNET III Cable |

MR-J3BUS_M [m (ft)] (*2) |

LD77MH MR-J3(W)-_B/MR-J3(W)-_B MR-J3(W)-_B; Standard cord for inside panel; 0.15 (0.49), 0.3 (0.98), 0.5 (1.64), 1 (3.28), 3 (9.84) | |

|

MR-J3BUS_M-A [m (ft)] (*2) |

LD77MH MR-J3(W)-_B/MR-J3(W)-_ MR-J3(W)-_B; Standard cable for outside panel; 5 (16.40), 10 (32.81), 20 (65.62) | ||

|

MR-J3BUS_M-B [m (ft)] (*2,*3) |

LD77MH MR-J3(W)-_B/MR-J3(W)-_B MR-J3(W)-_B; Long distance cable; 30 (98.43 ), 40 (131.23), 50 (164.04) | ||

|

5VDC Internal Current Consumption (A) |

0.55 |

0.70 | |

|

Flash ROM Write Count |

Max. 100000 times | ||

|

Number of Occupied I/O Points (points) |

32 (I/O assignment: Intelligent function module 32 points) | ||

|

Number of Applicable Modules |

Up to 5 modules | ||

|

Outline Dimensions W x H x D mm (in) |

45.0 x 90.0 x 95.0 (1.77 x 3.54 x 3.74) | ||

|

Weight (kg) |

0.22 | ||

|

External Command Signal |

Switching Signal |

DI signal (External start or speed-position switching can be selected by parameter.) | |

Notes:

- In speed-position switching control (ABS mode), the control unit available is “degree” only.

- _ = Cable length: (015: 0.15m (0.49ft.), 03: 0.3m (0.98ft.), 05: 0.5m (1.64ft.), 1: 1m (3.28ft.), 3: 3m (9.84ft.), 5: 5m (16.40ft.), 10: 10m (32.81ft.), 20: 20m (65.62ft.), 30: 30m (98.43ft.), 40: 40m (131.23ft.), 50: 50m (164.04ft.) )

- For the cable of less than 30(m)(98.43(ft.)), contact your nearest Mitsubishi sales representative.

LD77MH_ Input/Output (X/Y) Comparisons

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Pin Layout |

Pin No. |

Signal Name |

Pin No. |

Signal Name |

|

|

1 |

5V |

14 |

5V |

|

2 |

SG |

15 |

SG | |

|

3 |

HA (*1, *2, *3) |

16 |

HB (*1, *2, *3) | |

|

4 |

HAH (*1, *2, *4) |

17 |

HBH (*1, *2, *4) | |

|

5 |

HAL (*1, *2, *4) |

18 |

HBL (*1, *2, *4) | |

|

6 |

No connect (*5) |

19 |

No connect (*5) | |

|

7 |

20 | |||

|

8 |

21 | |||

|

9 |

22 | |||

|

10 |

EMI |

23 |

EMI, COM | |

|

11 |

DI1(*6) |

24 |

DI2(*6) | |

|

12 |

DI3 (*6) |

25 |

DI4 (*6) | |

|

13 |

COM (*7) |

26 |

COM (*7) |

Notes:

Input type from manual pulse generator/incremental synchronous encoder is switched in “ Pr.89 Manual pulse generator/Incremental synchronous encoder input type selection”. (Only the value specified against the axis 1 is valid.)

• 0: Differential-output type (Default value)

• 1: Voltage-output/open-collector type

Set the signal input form in “Pr.24 Manual pulse generator/Incremental synchronous encoder input selection”.

Voltage-output/open-collector type - Connect the A-phase/PLS signal to HA, and the B-phase/SIGN signal to HB.

Differential-output type - Connect the A-phase/PLS signal to HAH, and the A-phase/PLS inverse signal to HAL. Connect the B-phase/SIGN signal to HBH, and the B-phase/SIGN inverse signal to HBL.

Do not connect to any of the terminal is explained as “No connect”.

Set the external command signal (DI) in “ Pr.95 External command signal selection” at LD77MH16 use.

“COM” is the common terminal of DI1, DI2, DI3 and DI4.

Simple Motion Module QD77MS Parts List

|

Model Number |

Description |

Stocked Items |

|

QD77MS16 |

Up to 16 axes control |

S |

|

QD77MS4 |

Up to 4 axes control |

S |

|

QD77MS2 |

Up to 2 axes control |

S |

|

MR-HDP01 |

Manual pulse generator, Pulse resolution: 25PLS/rev(100PLS/rev after magnification by 4). Permitted speed: 200r/min (Normal rotation) |

S |

|

GX Works2 |

SW1DNC-GXW2-E, Sequence program creation, QD77MS setting |

S |

|

MR Configurator2 |

SW1DNC-MRC2-E, Servo amplifier MR-J4 series setting and adjustment |

S |

|

Cables and Accessories | ||

|

MR-J3BUS_M |

SSCNET III cable, Standard cord for inside panel. (_ = available lengths in meters: 0.15, 0.3, 0.5, 1, 3) |

S |

|

MR-J3BUS_M-A |

SSCNET III cable, Standard cord for outside panel. (_ = available lengths in meters: 5, 10, 20) |

S |

|

MR-J3BUS_M-B (*2) |

SSCNET III cable, long distance cable. (_ = available lengths in meters: 30, 40, 50) |

S |

|

Manuals | ||

|

IB(NA)-0300174-B(1202)MEE |

QD77MS/LD77MH Simple Motion Module Users Manual (synchronous control) |

MEAU.com |

|

IB-(NA)-0300185-A(1202)MEE |

Melsec-Q QD77MS Simple Motion Module Users Manual (positioning control) |

MEAU.com |

Notes:

- Please contact your nearest Mitsubishi sales representative for the cable of 100m.

- _=Cable length (015: 0.15m (0.49ft.), 03: 0.3m (0.98ft.), 05: 0.5m (1.64ft.), 1: 1m (3.28ft.), 3: 3m (9.84ft.), 5: 5m (16.40ft.), 10: 10m (32.81ft.), 20: 20m (65.62ft.), 30: 30m (98.43ft.), 40: 40m (131.23ft.), 50: 50m (164.04ft.))

QD77MS Input/Output (X/Y) Comparisons

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Simple Motion Module QD77MS Performance Specifications

|

Model Number |

QD77MS16 |

QD77MS4 |

QD77MS2 (*3) | |

|

Stocked Item |

S |

S |

S | |

|

No. of Control Axes |

16 axes |

4 axes |

2 axes | |

|

Operation Cycle |

0.88 ms / 1.77 ms (*1) |

0.88 ms |

0.88 ms | |

|

Interpolation Function |

Linear interpolation (Up to 4 axes), Circular interpolation (2 axes) | |||

|

Control System |

PTP (Point To Point) control, Path control (both linear and arc can be set), Speed control, Torque control, Speed-position switching control, Position-speed switching control | |||

|

Acceleration/Deceleration Process |

Trapezoidal acceleration/deceleration, S-pattern acceleration/deceleration | |||

|

Compensation Function |

Backlash compensation, Electronic gear, Near pass function | |||

|

Synchronous Control |

External encoder, Cam, Phase Compensation, Cam auto-generation function | |||

|

Control Unit |

mm, inch, degree, PLS | |||

|

Positioning Data |

600 data (positioning data No. 1 to 600)/axis (Can be set with MELSOFT GX Works2 or PLC program.) | |||

|

Backup |

Parameters, positioning data, and block start data can be saved on flash ROM (battery-less backup) | |||

|

OPR Control |

Machine OPR Control |

Near-point dog method, Count method 1, Count method 2, Data set method, Scale origin signal detection method | ||

|

Fast OPR Control |

Provided | |||

|

Sub Functions |

OPR retry, OP shift | |||

|

Positioning |

Linear Control |

1-axis linear control, 2-axis linear interpolation control, 3-axis linear interpolation control, 4-axis linear interpolation control (*4) (Composite speed, Reference axis speed) | ||

|

Fixed-Feed Control |

1-axis fixed-feed control, 2-axis fixed-feed control, 3-axis fixed-feed control, 4-axis fixed-feed control | |||

|

2-Axis Circular Interpolation Control |

Sub point designation, center point designation | |||

|

Speed Control |

1-axis speed control, 2-axis speed control, 3-axis speed control, 4-axis speed control | |||

|

Speed-Position Switching Control |

INC mode, ABS mode | |||

|

Position-Speed Switching Control |

INC mode | |||

|

Current Value Changing |

Changing to a new current value using the positioning data , Changing to a new current value using the start No. | |||

|

NOP Instruction |

Provided | |||

|

JUMP Instruction |

Unconditional JUMP, Conditional JUMP | |||

|

LOOP, LEND |

Provided | |||

|

High-Level Positioning Control |

Block start, Condition start, Wait start, Simultaneous start, Repeated start | |||

|

Manual Control |

JOG Operation |

Provided | ||

|

Inching Operation |

Provided | |||

|

Manual Pulse Generator Operation |

Possible to connect 1 module (Incremental) Unit magnification (1 to 10000 times) | |||

|

Expansion Control |

Speed-Torque Control |

Speed control without positioning loops, Torque control without positioning loops, Tightening & Press-fit control | ||

|

Absolute Position System |

Made compatible by setting battery to servo amplifier | |||

|

Synchronous Encoder Interface |

Up to 4 channel (internal interface, servo amplifier, via the PLC CPU interface) | |||

|

Internal Interface |

1 channel (Incremental) | |||

|

Functions That Limit Control |

Speed Limit Function |

Speed limit value, JOG speed limit value | ||

|

Torque Limit Function |

Torque limit value_same setting, torque limit value_individual setting | |||

|

Forced Stop Function |

Valid/Invalid setting | |||

|

Software Stroke Limit Function |

Movable range check with current feed value, movable range check with machine feed value | |||

|

Hardware Stroke Limit Function |

Provided | |||

|

Functions That Change Control Details |

Speed Change Function |

Provided | ||

|

Override Function |

Provided | |||

|

Acceleration/Deceleration Time Change Function |

Provided | |||

|

Torque Change Function |

Provided | |||

|

Target Position Change Function |

Target position address and target position speed are changeable | |||

|

Other Functions |

M Code Output Function |

Provided | ||

|

Step Function |

Deceleration unit step, Data No. unit step | |||

|

Skip Function |

Via sequence CPU, Via external command signal | |||

|

Teaching function |

Provided | |||

|

Mark Detection Function |

Continuous Detection mode, Specified Number of Detections mode, Ring Buffer mode | |||

|

Mark Detection Signal |

4 points |

2 points | ||

|

Mark Detection Setting |

16 |

4 | ||

|

Optional Data Monitor Function |

4 points/axis | |||

|

Amplifier-less Operation Function |

Provided | |||

|

Digital Oscilloscope Function |

Bit data:16 channels,

|

Bit data: 8 channels, Word data: 4 channels | ||

|

No. of Occupied I/O Points (Points) |

32 (I/O assignment: Intelligent function module 32 points) | |||

|

Dimensions W x H x D mm (in) |

27.4 x 98 x 90 (1.08 x 3.86 x 3.5) | |||

|

Weight kg |

0.16 |

0.15 | ||

Notes:

- Default value is 1.77 ms. If necessary, check the operation time and change to 0.88 ms.

- 8CH word data and 8CH bit data can be displayed in real time.

- The maximum number of control axes for QD77MS2 is two axes. Use QD77MS4 or QD77MS16 to control three or more axes.

- 4-axis linear interpolation control is effective only for the reference axis speed.