MR-E Super Servomotors and Amplifiers

Сопутствующее оборудование - Контроллеры FX1N/2N/2NC

|

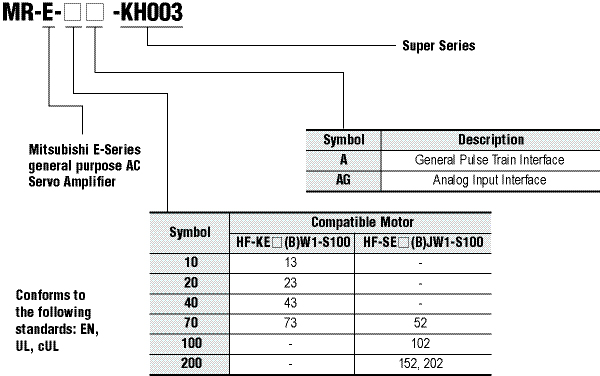

Код для заказа |

Иллюстрация |

Модель |

Описание |

|

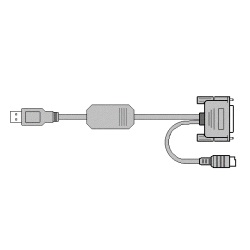

43393 |

|

SC09 |

Кабель-конвертер RS232C/RS422 для соединения PC и ПЛК MELSEC (FX, A(nSH) и QnA(S)), 3 м |

|

165288 |

|

FX-USB-AW |

Кабель-конвертер USB/RS422 для соединения PC и ПЛК MELSEC (FX), 3м |

|

139418 |  |

FX1N-4EX-BD |

Интерфейсный адаптер; 4 цифр. входа; для FX1S и FX1N |

|

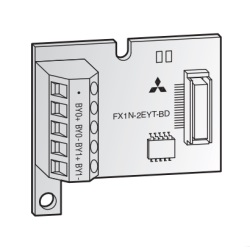

139420 |

FX1N-2EYT-BD |

Интерфейсный адаптер; 2 цифр. выхода; для FX1S и FX1N | |

|

139421 |

|

FX1N-2AD-BD |

Интерфейсный адаптер;2 аналог. входа;12 bit для FX1S и FX1N |

|

139422 |

FX1N-1DA-BD |

Интерфейсный адаптер;1 аналог. выход;12 bit для FX1S и FX1N | |

|

130743 |

|

FX1N-232-BD |

Встраиваемый модуль:RS-232 - интерфейс; |

|

130741 |

|

FX1N-422-BD |

Встраиваемый модуль:RS-422 - интерфейс; |

|

130742 |

|

FX1N-485-BD |

Встраиваемый модуль:RS-485 - интерфейс; |

|

65596 |

|

FX2N-232-BD |

Встраиваемый модуль:RS-232 - интерфейс; |

|

65595 |

|

FX2N-422-BD |

Встраиваемый модуль:RS-422 - интерфейс; |

|

65597 |

|

FX2N-485-BD |

Встраиваемый модуль:RS-485 - интерфейс; |

|

130745 |

|

FX1N-CNV-BD |

Специальный коммуникационный адаптер FX1S и FX1N для FX0N и FX2N/FX2NC |

|

65598 |

FX2N-CNV-BD |

Специальный коммуникационный адаптер для FX0N/FX2N | |

|

70880 |

|

FX2N-CNV-BC |

Разъем для подключения модулей расширения кабелем FX0N-65EC |

|

104508 |

|

FX2NC-CNV-IF |

Специальный коммуникационный адаптер для FX2N, FX0N или FX |

|

130746 |

|

FX1N-EEPROM-8L |

Кассета памяти EEPROM; 8000 steps PLC program; with FX1S/FX1N |

|

23826 |

FX-EEPROM-8 |

Кассета памяти EEPROM; 8000 steps PLC program; with FX2N | |

|

65600 |

FX-EEPROM-16 |

Кассета памяти EEPROM; 16000 steps PLC program; with FX2N | |

|

141528 |

FX2N-ROM-E1 |

Кассета памяти 16K EEPROM, с переключателем разрешения записи; для FX2N | |

|

104507 |

FX2NC-EEPROM-16 |

Кассета памяти 16K steps EEPROM с переключателем разрешения записи; | |

|

149016 |

FX2NC-ROM-EC1 |

Кассета памяти 16K steps EEPROM с переключателем разрешения записи; часы реального времени, | |

|

137206 |

|

FX2NC-RTC |

Адаптер для часов реального времени для FX2NC |

|

56173 |

|

CR01-R4/R4 |

Преобразователь интерфейса RS422 and RS422; опторазвязка |

|

56172 |

|

CR01-R2/R4 SET |

Преобразователь интерфейса RS232/RS422 and RS422; опторазвязка |

|

3386 |

|

Switch-Box |

Иммитатор срабатывания дискретных сигналов (12 переключателей) |

|

66513 |

Input-SIM: FX2N |

Иммитатор срабатывания дискретных сигналов (8 переключателей) | |

|

65081 |

Input-SIM: FX1S/FX1N |

Иммитатор срабатывания дискретных сигналов (8 переключателей) | |

|

210092 |

|

FX1N-BAT |

Батарея для MELSEC FX1N |

|

5142 |

F2-40BL |

Батарея для MELSEC FX/FX2N | |

|

128725 |

FX2NC-32BL |

Батарея для MELSEC FX2NC | |

|

128731 |

|

E-GMC-200CAB |

Кабель FX2N-XXGM --> MR-C (XX = 10 oder 20) |

|

125583 |

|

E-GMJ2-200CAB1A |

Кабель FX2N-XXGM --> MR-J2 |

|

130450 |

|

E-GM-200CAB |

Кабель FX2N-XXGM --> многофункц. (XX = 10 oder 20) |

|

125189 |

|

FX-16E-TB/UL |

Клеммная колодка 16 I/O |

|

128724 |

|

FX-32E-TB/UL |

Клеммная колодка 32 I/O |

|

125584 |

|

FX-16E-150CAB |

Кабель 1,5 m FX2N-XXGM --> в клеммную колодку (XX = 10 oder 20) |

|

128722 |

FX-16E-300CAB |

Кабель 3 m FX2N-XXGM --> в клеммную колодку (XX = 10 oder 20) | |

|

130451 |

FX-16E-500CAB |

Кабель 5 m FX2N-XXGM --> в клеммную колодку (XX = 10 oder 20) | |

|

128723 |

|

FX-16E-500CAB-S |

Кабель 5 m FX2N-XXGM --> внешние у-ва (XX = 10 oder 20) |

|

149148 |

|

TB-20-S |

Клеммная колодка, 20 pin., витовой клемник |

|

149023 |

TB-20-C |

Клеммная колодка, 20 pin., защелк. соеденение | |

|

149038 |

|

TB-EX-CAB-1M |

Кабель 1 m для терминальной колодки TB-EX / TB-20 |

|

149039 |

TB-EX-CAB-3M |

Кабель 3m для терминальной колодки TB-EX / TB-20 | |

|

149040 |

TB-EX-CAB-5M |

Кабель 5m для терминальной колодки TB-EX / TB-20 | |

|

45348 |

|

FX0N-65EC |

Кабель соединения базового блока и модулей расш-я MELSEC FX0N/FX2N; 0.65 m |

|

31870 |

|

FX-20P-CADP |

Кабель-адаптер для MELSEC FX0S/FX0N/FX2N/FX2NC и периферийных устройств MELSEC FX; разъём D-SUB 25 -> miniDin 8; 0.3 м |

|

248245 |

|

FX-20P-CAB0 |

Кабель FX0S/FX0N/FX2N/FX2NC и FX-10P-E/FX-20P-E-SET0/FX-10DM-E; 3 m |

|

104509 |

|

FX2NC-100MPCB |

Кабель питания для FX2NC, 1 m |

|

104510 |

|

FX2NC-100BPCB |

Кабель к источнику питания для модулей FX3UC/FX2NC, 1 m |

|

129197 |

|

FX1N-5DM |

Дисплейный модуль для FX1S и FX1N |

|

132600 |

|

FX-10DM-E |

Панель управления и отображения MELSEC FX1S/FX1N/FX2N |

|

149036 |

|

TB-CON10-C |

Коннектор для модулей расш-я FX2NC, 10 pin |

|

149144 |

|

TB-8EX-S |

Клеммник для внешних сигналов 8 входов, винтовое соединение |

|

149145 |

TB-8EX-C |

Клеммник для внешних сигналов 8 входов, защелк. соеденение | |

|

149021 |

TB-16EX-S |

Клеммник для внешних сигналов 16 входов, винтовое соединение | |

|

149022 |

TB-16EX-C |

Клеммник для внешних сигналов 16 входов, защелк. соеденение | |

|

149044 |

|

TB-8EY-S |

Терминальная колодка для 8 выходов; гнезда для реле или транз, винтовое соединение |

|

149045 |

TB-8EY-C |

Терминальная колодка для 8 выходов; гнезда для реле или транз, защелк. соеденение | |

|

149041 |

|

TB-EY-CAB-1M |

Соединительный кабель 1 m для TB-EY |

|

149042 |

TB-EY-CAB-3M |

Соединительный кабель 3 m для TB-EY | |

|

149043 |

TB-EY-CAB-5M |

Соединительный кабель 5 m для TB-EY | |

|

149034 |

|

TB8-RELAY-6A |

Выносной блок для 8 реле 6A; для TB-8EY и ST16-SOCKET |

|

149035 |

TB8-TRANSISTOR-2A |

Выносной блок для 8 транзисторов 2A; для TB-8EY и ST16-SOCKET | |

|

149146 |

|

TB-PIB-RD |

Аксессуар для колодок TB, шлейф 500 mm; для TB-8EY, красный |

|

149147 |

|

TB-PIB-BL |

Аксессуар для колодок TB, шлейф 500 mm; для TB-8EY, синий |

|

149158 |

|

TB-SP |

Аксессуар для колодок TB, разделительная пластина для TB-8EY |

|

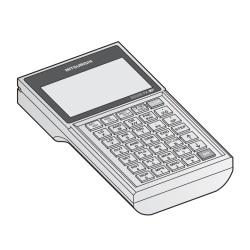

221271 |

|

FX-30P |

Ручной программатор для серии FX |

Сопутствующее оборудование - Контроллеры FX1S

|

Код для заказа |

Иллюстрация |

Модель |

Описание |

|

43393 |

|

SC09 |

Кабель-конвертер RS232C/RS422 для соединения PC и ПЛК MELSEC (FX, A(nSH) и QnA(S)), 3 м |

|

165288 |

|

FX-USB-AW |

Кабель-конвертер USB/RS422 для соединения PC и ПЛК MELSEC (FX), 3 м |

|

139418 |

|

FX1N-4EX-BD |

Интерфейсный адаптер; 4 цифр. входа; для FX1S и FX1N; Note: использовать только совместно с фирменным софтом 2.00! Для FX1S/FX1N |

|

139420 |

FX1N-2EYT-BD |

Интерфейсный адаптер; 2 цифр. выхода; для FX1S и FX1N; Note: использовать только совместно с фирменным софтом 2.00! Для FX1S/FX1N | |

|

139421 |

|

FX1N-2AD-BD |

Интерфейсный адаптер;2 аналог. входа;12 bit для FX1S и FX1N; |

|

139422 |

FX1N-1DA-BD |

Интерфейсный адаптер;1 аналог. выход;12 bit для FX1S и FX1N; | |

|

130743 |

|

FX1N-232-BD |

Встраиваемый модуль:RS-232 - интерфейс; |

|

130741 |

|

FX1N-422-BD |

Встраиваемый модуль:RS-422 - интерфейс; |

|

130742 |

|

FX1N-485-BD |

Встраиваемый модуль:RS-485 - интерфейс; |

|

130745 |

|

FX1N-CNV-BD |

Коммуникационный адаптер для FX1S и FX1N, для FX0N и FX2N/FX2NC исп. спец. модуль |

|

130744 |

|

FX1N-8AV-BD |

Аналоговый задатчик установок для FX1S |

|

130746 |

|

FX1N-EEPROM-8L |

EEPROM кассета памяти; 8000 steps PLC program; для FX1S/FX1N |

|

129197 |

|

FX1N-5DM |

Дисплейный модуль для FX1S и FX1N |

|

132600 |

|

FX-10DM-E |

Панель управления и отображенияr MELSEC FX1S/FX1N/FX2N |

|

3386 |

|

Switch-Box |

Приставка имитации состояния цифровых входов (12 переключателей) |

|

65081 |

Input-SIM: FX1S/FX1N |

Приставка имитации состояния цифровых входов (8 переключателей) | |

|

149109 |  |

FX-20P-E-SET0 |

Ручной программатор с RAM и кабелем FX-20P-CAB0 |

|

23819 |

FX-20P-ADP |

Адаптер питания для программатора FX-20P-E |

Сопутствующее оборудование - Контроллеры ALPHA XL

|

Код для заказа |

Иллюстрация |

Модель |

Описание |

|

142528 |

|

AL2-GSM-CAB |

Кабель для соединения AlphaXL с GSM модемом |

|

231365 |

|

AL2-FRAME-10-IP40 |

AL2-FRAME-10-IP40 Панель-обрамление для AL2-10 степень защиты IP40 |

|

231366 |

|

AL2-FRAME-14/24-IP40 |

AL2-FRAME-14/24-IP40 Панель-обрамление для AL2-14/24 степень защиты IP40 |

|

231367 |

|

AL2-FRAME-10-IP54 |

AL2-FRAME-10-IP54 Панель-обрамление для AL2-10 степень защиты IP54 |

|

231368 |

|

AL2-FRAME-14/24-IP54 |

AL2-FRAME-14/24-IP40 Панель-обрамление для AL2-14/24 степень защиты IP54 |

|

124894 |

|

AL-ASI-BD |

Модуль ASI - интерфейса |

|

87673 |

|

AL-EEPROM |

Модуль расширения памяти |

|

87674 |

|

AL-232CAB |

Кабель для программирования Alpha(XL)-PC |

|

209029 |  |

ALPHA POWER 24-0.75 |

Источник питания Вход 100-240V AC; Выход 24V DC / 0,75A |

|

209030 |

ALPHA POWER 24-1.75 |

Источник питания Вход 100-240V AC; Выход 24V DC / 1,75A | |

|

209031 |

ALPHA POWER 24-2.5 |

Источник питания Вход 100-240V AC; Выход 24V DC / 2,5A |

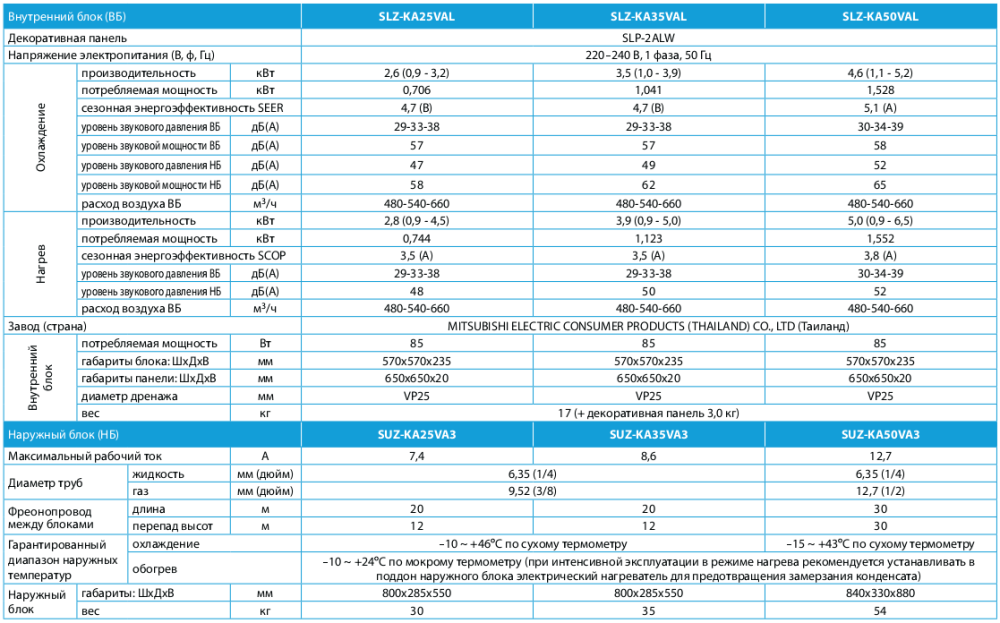

| FR-S520SE-0,2К-EC | FR-S520SE-0,4K-EC | FR-S520SE-0,75K-EC | FR-S520SE-1,5K-EC | FR-S540E-0,4K-EC | FR-S540E-0,75K-EC | FR-S540E-1,5K-EC | FR-S540E-2,2K-EC | FR-S540E-3,7K-EC | |||

| Выход | Мощность двигателя, кВт | 0.2 | 0.4 | 0.75 | 1.5 | 0.4 | 0.75 | 1.5 | 2.2 | 3.7 | |

| Полная мощность, кВА | 0.5 | 1.0 | 1.6 | 2.8 | 0.9 | 1.6 | 2.7 | 3.7 | 5.9 | ||

| Номинальный ток, А | 1.4 | 2.5 | 4.1 | 7.0 | 1.2 | 2.3 | 3.7 | 5.3 | 7.7 | ||

| Перегрузочная способность | 200% от номин. мощности двигателя в течении 0.5с; 150% в течении 60с (при температуре <50°С) | ||||||||||

| Напряжение | 3-фазное, от 0В до напряжения питания | ||||||||||

| Вход | Напряжение питания | 1-фазное, 200-240В AC, -15% / +10% | 3-фазное, 380-480В AC, -15% / +10% | ||||||||

| Допустимое напряжение питания | 170-264В AC при 50 / 60 Гц | 325-528В AC при 50 / 60 Гц | |||||||||

| Частота питающей сети | 50 / 60 Гц ± 5% | ||||||||||

| Номинальная мощность, кВА | 0.9 | 1.5 | 2.5 | 4.4 | 1.5 | 2.5 | 4.5 | 5.5 | 9.5 | ||

| Общие характеристики | Способ управления | V/f-управление или автоматическая регулировка момента на валу | |||||||||

| Способ модуляции | Синусоидальная ШИМ, мягкая ШИМ | ||||||||||

| Частота несущей ШИМ, кГц | 0.7 - 14,5 (устанавливается пользователем) | ||||||||||

| Диапазон выходной частоты, Гц | 0.5-120 | ||||||||||

| Разрешающая способность ввода частоты | Аналоговая | Для входа 2-5: 1/500 от макс. заданной частоты (вход 5 В DC); 1/1000 (вход 10 В, 20 мА DC) | |||||||||

| Цифровая | 0,01 Гц / 50 Гц (включая импульсный вход) | ||||||||||

| Точность задания частоты | ± 1 % от макс. выходной частоты (при температуре 25°С ±10 °С) при аналоговом задании;

± 0,5 % от макс. выходной частоты (с помощью поворотного регулятора) при цифровом задании | ||||||||||

| Вольт / частотная характеристика | основная частота регулируется в диапазоне от 0 до 120 Гц | ||||||||||

| Пусковой момент | > 150 % / 6 Гц (с функцией автоматического поддержания момента) | ||||||||||

| Увеличение момента | Ручное, с регулировкой уровня напряжения в диапазоне 0-30 % | ||||||||||

| Время разгона / замедления | 0.01 до 999 сек. (раздельная установка для разгона и замедления) | ||||||||||

| Характеристики разгона / замедления | Линейная или S-образная характеристика | ||||||||||

| Момент торможения | с рекуперацией | 150 % | 100 % | 100 % | 50 % | 100 % | 100 % | 50 % | 20 % | 20 % | |

| пост. током | С регулировкой времени и усилия торможения.

Рабочая частота: 0-120 Гц, время активизации: 0-10 сек., напряжение 0-15 % (регулируется извне) | ||||||||||

| Уровень тока для функции предотвращения опрокидывания | Установка уровня рабочего тока 0-20 %, устанавливается пользователем | ||||||||||

| Функция ограничения допустимого тока | Уровень активизации зафиксирован, устанавливается только необходимость активизации | ||||||||||

| Защита двигателя | Электронная тепловая защита (с регулировкой номинального тока) | ||||||||||

| Сигналы цепей управления | Сигналы задания частоты | аналоговое | 0-5 В DC, 0-10 В DC, 0/4-20 мА | ||||||||

| цифровое | от пульта управления, по интерфейсу RS-485 | ||||||||||

| Функции дискретных входов | Управление | Отдельные входы для пуска в прямом и обратном направлении (импульсный или с фиксацией) | |||||||||

| Ступенчатое задание | До 15 значений выходной частоты в диапазоне 0-120 Гц может быть установлено.

Текущая скорость может быть скорректирована непосредственно во время работы с пульта управления. | ||||||||||

| 2-й набор параметров | Активизация 2-го набора параметров (время разгона, время замедления, уровень увеличения напряжения на малых частотах, основная частота, электронная защита от перегрузки по току) | ||||||||||

| Токовый вход | Задание частоты токовым сигналом 0/4-20 мА DC (клемма 4) | ||||||||||

| Внешнее тепловое реле | Останов инвертора при активизации внешнего теплового реле | ||||||||||

| Выбор режима управления | Переключение режимов "PU" (от пульта управления) и "External" (от внешних сигналов) | ||||||||||

| Выбор режима управления | Переключение режимов "PU" (от пульта управления) и "External" (от внешних сигналов) | ||||||||||

| ПИД-регулятор | Активизация режима ПИД-регулирования | ||||||||||

| Стоп выбегом | Немедленное отключение выхода инвертора | ||||||||||

| Сброс аварии | Индикация состояния аварии сбрасывается одновременно со сбросом защитной функции | ||||||||||

| Функциональный набор | Установка максимального и минимального значения выходной частоты, обход резонансных частот, вход для контакта внешнего теплового реле, перезапуск после кратковременного провала питания, предотвращения вращения в обратном направлении, компенсация скольжения, выбор режима управления, ПИД-регулятор | ||||||||||

| Функции дискретных выводов | Сигнализация текущего состояния | 1 программируемый выход (выход с открытым коллектором):

1 релейный выход с коммутационными параметрами 230 В АС; 0.3 A / 30 B DC; 0.3A

| |||||||||

| Аналоговый сигнал | Отображение выходной частоты, выходного тока ; аналоговый выход (0-5 В / 1 мА вся шкала) | ||||||||||

| Пульт управления | Показания встроенного пульта | Рабочее состояние | Выходное напряжение, ток двигателя, заданная частота, скорость вращения | ||||||||

| Состояние сбоя | Аварийное сообщение отображается после активизации защитной функции. 4 последних сбоя сохраняются в памяти | ||||||||||

| Дополнительные показания пульта FR-PU04 | Рабочее состояние | Состояние сигналов на входных и выходных клеммах | |||||||||

| Помощь | Интерактивная система помощи при возникновении сбоя | ||||||||||

| Защита | Функции | Перегрузка по току (при разгоне, замедлении и постоянной скорости), генераторный режим недопустимой интенсивности ( при разгоне, замедлении и постоянной скорости), внезапный провал питания, тепловая перегрузка инвертора/двигателя, перегрев радиатора, сбой работы вентилятора, перегрузка по току, замыкание на землю при запуске, активизация внешнего теплового реле двигателя, ошибка подключения пульта управления, превышение допустимого числа перезапусков, коммуникационная ошибка, ошибка CPU, повышенный уровень напряжения | |||||||||

| Структура защиты | IP20

| ||||||||||

| Прочие | Охлаждение | Естественное | Естественное | Принудительное | Естественное | Принудительное | |||||

| Потери, Вт | 20 | 45 | 50 | 85 | 40 | 50 | 80 | 110 | 170 | ||

| Габаритные размеры | Ширина | 68 мм | 68 мм | 68 мм | 108 мм | 108 мм | 108 мм | 108 мм | 108 мм | 108 мм | |

| Высота | 128 мм | 128 мм | 128 мм | 128 мм | 128 мм | 128 мм | 128 мм | 128 мм | 128 мм | ||

| Глубина | 80.5 мм | 142.5 мм | 162.5 мм | 155.5 мм | 129.5 мм | 129.5 мм | 135.5 мм | 155.5 мм | 165.5 мм | ||

| Вес, кг | 0.6 | 0.8 | 1.0 | 1.5 | 1.5 | 1.5 | 1.5 | 1.6 | 1.7 | ||

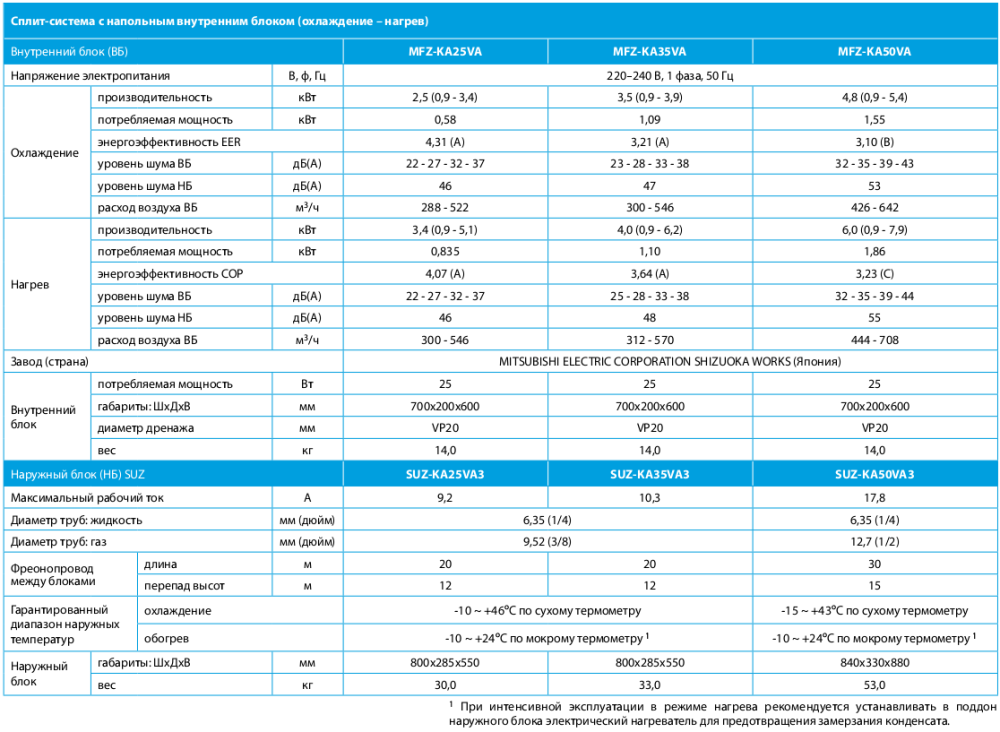

|

FR-F721-xxK |

5,5 |

7,5 |

11 |

15 |

18,5 |

22 |

30 |

37 |

45 |

55 |

|

Номинальная мощность двигателя (кВт) |

5,5 |

7,5 |

11 |

15 |

18,5 |

22 |

30 |

37 |

45 |

55 |

|

Номинальный ток (А) |

24 |

33 |

46 |

61 |

76 |

90 |

115 |

145 |

175 |

215 |

|

Напряжение питания (В) |

3*220-240/50Гц | |||||||||

|

Вес инвертора (кг) |

20 |

22 |

33 |

35 |

50 |

52 |

69 |

87 |

90 |

120 |

|

FR-F741-xxK |

5,5 |

7,5 |

11 |

15 |

18,5 |

22 |

30 |

37 |

45 |

55 |

|

Номинальная мощность двигателя (кВт) |

5,5 |

7,5 |

11 |

15 |

18,5 |

22 |

30 |

37 |

45 |

55 |

|

Номинальный ток (А) |

12 |

17 |

23 |

31 |

38 |

44 |

57 |

71 |

86 |

110 |

|

Напряжение питания (В) |

трехфазная сеть ~380 В (50 Гц) | |||||||||

|

Вес инвертора (кг) |

25 |

26 |

37 |

40 |

48 |

49 |

65 |

80 |

83 |

115 |

|

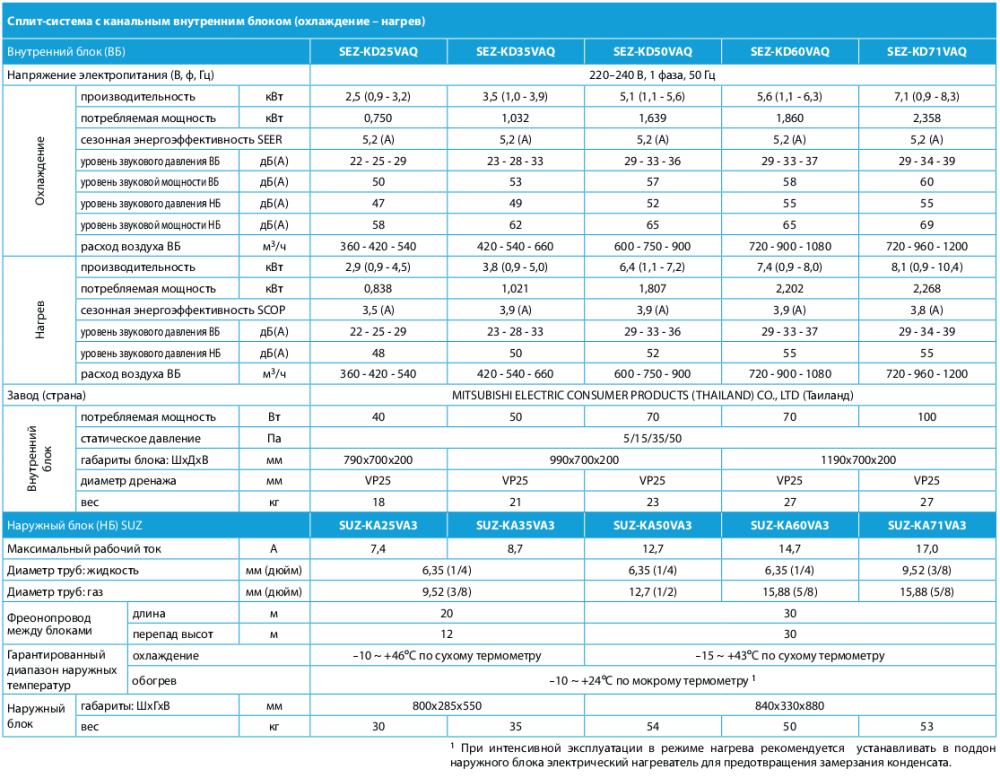

Серия |

FR-Е 520EC |

FR-Е 540EC | ||||||||||

|

Тип |

-0.4k |

-0.75k |

-1.5k |

-2.2k |

-0.4k |

-0.75k |

-1.5k |

-2.2k |

-3.7k |

-5.5k |

-7.5k | |

|

Выходные параметры | ||||||||||||

|

Мощность1двигателя, кВт |

Перегрузка 150% |

0.75 |

1.1 |

2.2 |

3 |

0.75 |

1.1 |

2.2 |

3 |

4 |

7.5 |

11 |

|

Перегрузка 200% |

0.4 |

0.75 |

1.5 |

2.2 |

0.4 |

0.75 |

1.5 |

2.2 |

4 |

5.5 |

7.5 | |

|

Номинальный ток *, А |

Перегрузка 150% |

3.6 |

5 |

9.6 |

12 |

1.8 |

3 |

4.9 |

6.7 |

9.5 |

14 |

21 |

|

Перегрузка 200% |

2.5 |

4 |

7 |

10 |

1.6 (1.4) |

2.6 (2.2) |

4 (3.8) |

6(5.4) |

9.5 (8.7) |

12 |

17 | |

|

Полная мощность, кВА |

0.95 |

1.5 |

2.7 |

3.8 |

1.2 |

2.0 |

3.0 |

4.6 |

7.2 |

9.1 |

13.0 | |

|

Перегрузочная способность2 |

Перегрузка 150% |

150% в течении 0.5 сек, 120% в течении 1 минуты. | ||||||||||

|

Перегрузка 200% |

200% в течении 0.5 сек, 150% в течении 1 минуты. | |||||||||||

|

Выходное напряжение3 |

Трехфазное, 0В – входное напряжение, настраивается | |||||||||||

|

Входные параметры | ||||||||||||

|

Входное напряжение |

1- фаза, ~200-240В (-15% / +10%) |

3 - фазы, ~380-480В (-15% / +10%) | ||||||||||

|

Частота |

50 / 60 Гц ± 5% |

| ||||||||||

|

Входная мощность4, кВА |

1.5 |

2.3 |

4.0 |

5.2 |

1.5 |

2.5 |

4.5 |

5.5 |

9 |

12 |

17 | |

|

Настройки и управление | ||||||||||||

|

Способ управления |

Векторное управление с самонастройкой на двигатель или U/f - управление | |||||||||||

|

Способ модуляции |

Синусоидальная ШИМ, «мягкая» ШИМ | |||||||||||

|

Частота модуляции, кГц |

0.7 – 14.5, программируется | |||||||||||

|

Выходная частота, Гц |

0.2 - 400 | |||||||||||

|

Точность поддержания частоты |

+0,2% от максимальной выходной частоты (диапазон температур 25 оС + 10 оС) через

| |||||||||||

|

Время разгона / торможения |

0; 0.1 – 3600 сек, настраивается | |||||||||||

|

Уровень токоограничения |

0 – 200%, настраивается | |||||||||||

|

Стартовый момент |

Настраивается | |||||||||||

|

Устройство торможения |

Встроенный тормозной транзистор, подсоединяемый резистор-гаситель, внешняя опция торможений | |||||||||||

|

Зависимость U / f |

Настраивается | |||||||||||

|

Сигналы задания

|

Аналоговые: 0-5В, 0-10В, 4-20мА; Цифровые: через пульт управления FR-PA02-02, или через RS485 | |||||||||||

|

Стартовый сигнал |

Старт в прямом направлении, старт в обратном направлении, старт запрещен | |||||||||||

|

Сброс защит |

Внешний сброс после срабатывания защиты | |||||||||||

|

Уставки скорости |

Могут быть установлены фиксированных 15 скоростей | |||||||||||

|

Второй набор параметров |

Выбирается внешней командой | |||||||||||

|

Jog режим |

Включается с пульта управления | |||||||||||

|

Тип логики |

Положительная или отрицательная логика; выбирается пользователем | |||||||||||

|

Электронное термореле |

Настраивается номинальный ток | |||||||||||

|

ЭМС / окружающая среда | ||||||||||||

|

ЭМС |

При использовании с фильтром, удовлетворяет стандарту EN500081 | |||||||||||

|

Класс защиты |

IP 20 | |||||||||||

|

Диапазон рабочих температур |

-10° С - +50° С | |||||||||||

|

Температура хранения |

От -20 оС до +65 оС | |||||||||||

|

Допустимая влажность |

Макс. 90% (без образования конденсата) | |||||||||||

|

Установка |

Макс. 1000 м над уровнем моря | |||||||||||

|

Ударное воздействие |

10g (трехкратно по трем направлениям) | |||||||||||

|

Максимальная вибрация |

0,6g | |||||||||||

|

Воздушная среда |

В закрытом помещении, без агрессивных газов, паров и пыли | |||||||||||

|

Охлаждение |

Самоохлаждение |

Принудительно |

Самоохлаждение |

Принудительно | ||||||||

Сноски:

- Указанное значение номинального тока соответствует номинальному напряжению электродвигателя 230В, 1 фаза, и 440В – 3 фазы при температуре окружающей среды +50оС.

- Перегрузочная способность указывается в процентах как отношение тока перегрузки к номинальному току преобразователя. При циклической нагрузке требуется время, чтобы температура преобразователя и двигателя установилась ниже или равной температуре, соответствующей 100% нагрузки.

- Максимальное входное напряжение не может превышать входного напряжения. Величина выходного напряжения может быть изменена программно, но должно соответствовать входному напряжению.

- Потребляемая мощность со стороны преобразователя может изменяться и зависит от разных факторов, включая наличие дросселей, фильтров, а также длины соединительных кабелей.

Информация MR-E Super

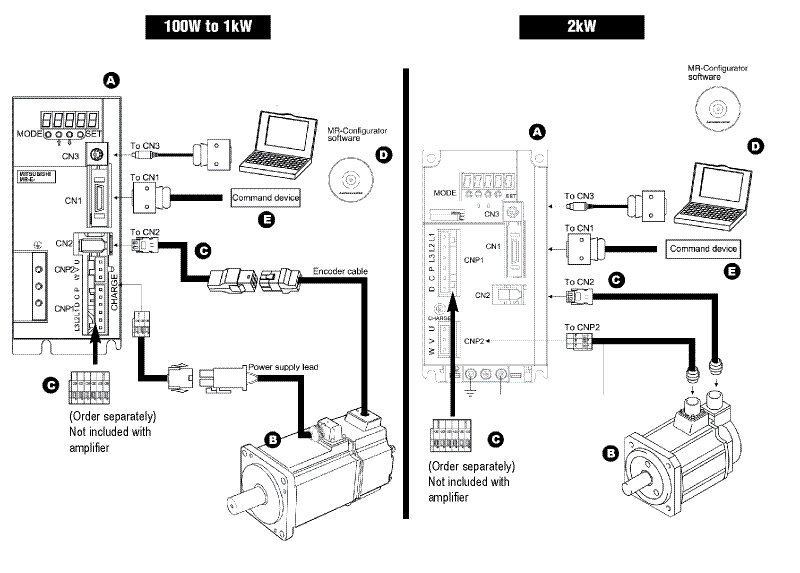

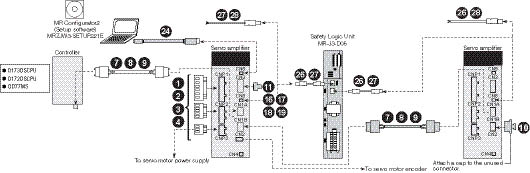

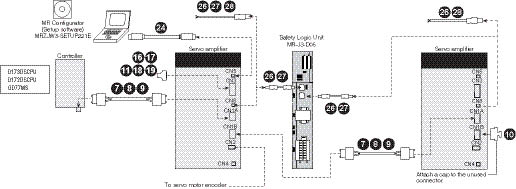

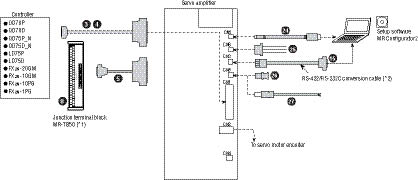

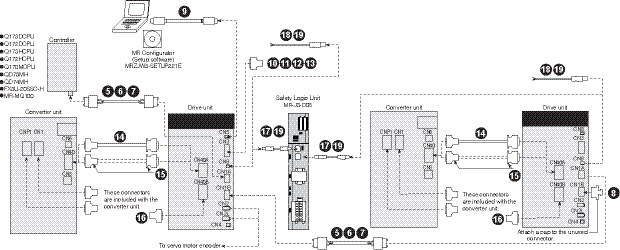

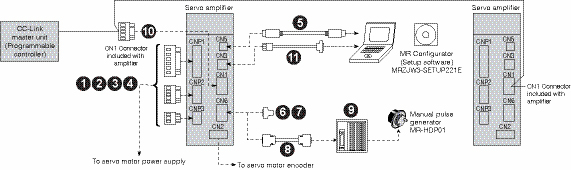

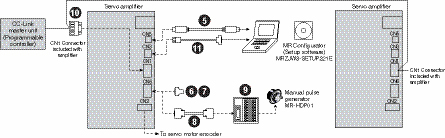

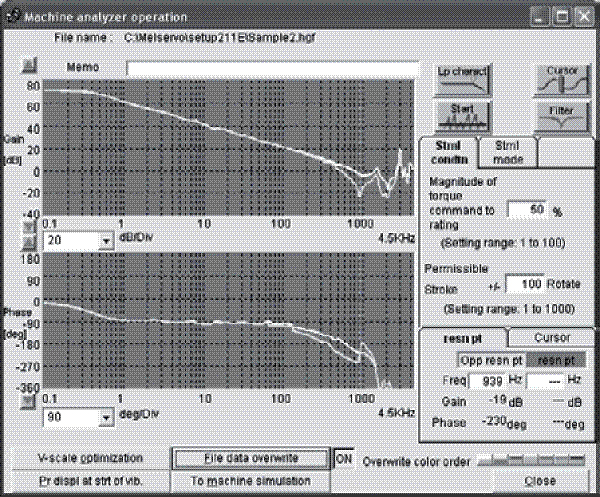

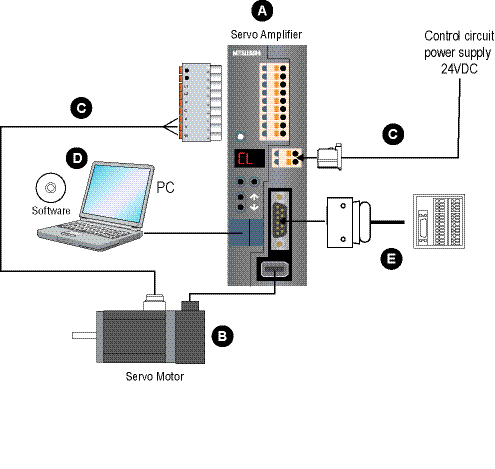

Overview and Configuration

High performance and compact, the MR-E Super is an excellent choice for applications up to 2kW. The MR-E Super is available in pulse-train position or analog speed/torque models. The amplifier features Mitsubishi Electric’s legendary auto-tuning and vibration suppression functions, a 400Hz analog frequency response, and accepts pulse commands up to 500kHz. The motors are low to medium inertia up to 4500rpm and are equipped with a 131,072 pulse per revolution encoder. Set-up and diagnosis is made easy with the MR-Configurator Windows® based software.

A. MR-E Super Amplifiers

B. MR-E Super Servomotors

C. Cables and Connectors

D. Software and Manuals

E. Optional Accessories

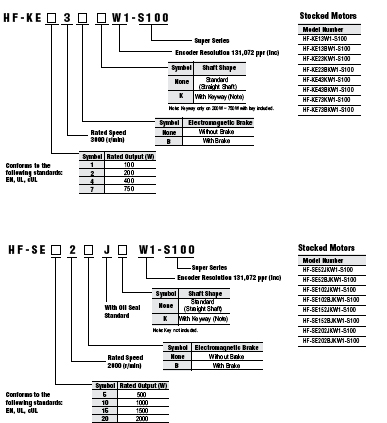

Motors

Servomotor Selection

|

Motor Series |

Rated Speed (Max. r/min) |

Rated Output Capacity (kW) |

Servomotor Brake (B) |

EN |

UL, cUL |

Protective Rating |

Features |

Application Examples | |

|

Small Capacity |

HF-KE Super Series

|

3000 (4500) |

4 Types

|

Yes |

Yes |

Yes |

IP55

|

Stable control from low speeds to high speeds allows compliance with a variety of applications. |

Belt Drive; Robots; Mounters; Sewing Machines; X-Y Tables; Food Processing Machines |

|

Medium Capacity |

HF-SE Super Series

|

2000 (3000) |

4 Types

|

Yes |

Yes |

Yes |

IP65

|

Material Handling Systems; Robots; X-Y Tables |

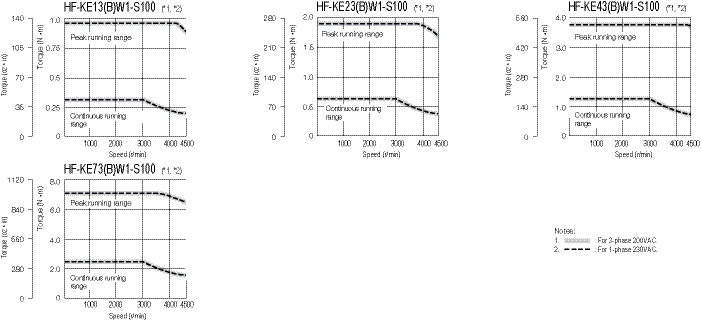

MR-E HF-KE Super 3000 r/min Series Servomotor Specifications

|

Servomotor Model |

HF-KE13W1-S100 |

HF-KE23W1-S100 |

HF-KE43W1-S100 |

HF-KE73W1-S100 | |

|

Servomotor Model with Brake |

HF-KE13BW1-S100 |

HF-KE23BW1-S100 |

HF-KE43BW1-S100 |

HF-KE73BW1-S100 | |

|

Compatible Servo Amplifier Model |

MR-E-10A-KH003 |

MR-E-20A-KH003 |

MR-E-40A-KH003 |

MR-E-70A-KH003 | |

|

Compatible Servo Amplifier with Analog Input Interface |

MR-E-10AG-KH003 |

MR-E-20AG-KH003 |

MR-E-40AG-KH003 |

MR-E-70AG-KH003 | |

|

Power Facility Capacity (kVA) (*1) |

0.3 |

0.5 |

0.9 |

1.3 | |

|

Continuous Running Duty |

Rated Output (W) |

100 |

200 |

400 |

750 |

|

Rated Torque (N·m [oz·in]) |

0.32 (45.3) |

0.64 (90.6) |

1.3 (184) |

2.4 (340) | |

|

Maximum Torque (N·m [oz·in]) |

0.95 (135) |

1.9 (269) |

3.8 (538) |

7.2 (1020) | |

|

Rated Speed (r/min) |

3000 | ||||

|

Maximum Speed (r/min) |

4500 | ||||

|

Permissible Instantaneous Speed (r/min) |

5175 | ||||

|

Power Rate At Continuous Rated Torque (kW/s) |

11.5 |

16.9 |

38.6 |

39.9 | |

|

Rated Current (A) |

0.8 |

1.4 |

2.7 |

5.2 | |

|

Maximum Current (A) |

2.4 |

4.2 |

8.1 |

15.6 | |

|

Regenerative Braking Frequency (Times/Min.) (*2, *3) |

With No Options |

(*4) |

(*4) |

249 |

140 |

|

MR-RB032 (30W) |

(*4) |

(*4) |

747 |

210 | |

|

MR-RB12 (100W) |

- |

(*4) |

2490 |

700 | |

|

MR-RB32 (300W) |

- |

- |

- |

2100 | |

|

Moment Of Inertia J (x10-4 kg • m²) [J (oz • in²)] |

Standard |

0.088 (0.481) |

0.24 (1.31) |

0.42 (2.30) |

1.43 (7.82) |

|

With Electromagnetic Brake |

0.090 (0.492) |

0.31 (1.69) |

0.50 (2.73) |

1.63 (8.91) | |

|

Recommended Load/Motor Inertia Moment Ratio |

Maximum of 15 times the servomotor’s inertia moment (*5) | ||||

|

Speed/Position Detector |

Incremental encoder (resolution per servomotor rotation: 131072 p/rev) | ||||

|

Structure |

Totally enclosed non ventilated (protection level: IP55) (*6) | ||||

|

Environment |

Ambient Temperature |

0 to 40°C (32 to 104°F) (non-freezing), storage: -15 to 70°C (5 to 158°F) (non-freezing) | |||

|

Ambient Humidity |

80% RH maximum (non-condensing), storage: 90% RH maximum (non-condensing) | ||||

|

Atmosphere |

Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist or dust | ||||

|

Elevation/Vibration (*7) |

1000m or less above sea level; X: 49m/s² Y: 49m/s² | ||||

|

Weight kg (lb) |

Standard |

0.56 (1.3) |

0.94 (2.1) |

1.5 (3.3) |

2.9 (6.4) |

|

With Electromagnetic Brake |

0.86 (1.9) |

1.6 (3.6) |

2.1 (4.7) |

3.9 (8.6) | |

Notes:

- The power facility capacity varies depending on the power supply’s impedance.

- The regenerative braking frequency shows the permissible frequency when the motor, without a load and the optional regeneration unit, decelerates from the rated speed to a stop. When a load is connected; however, the value will be the table value/(m+1), where m=the load inertia moment/the motor inertia moment. When the operating speed exceeds the rated speed, the regenerative braking frequency is inversely proportional to the square of (operating speed/rated speed). If the operating speed changes frequently or when the regeneration is constant (as with vertical feeds), find the regenerative heating value (W) in operation. Provisions must be made to keep this heating value below the tolerable regenerative power (W). Optimal regenerative resistor varies for each system. Refer to the section “Optional Accessories • Regenerative Brake Options” in this catalog for details on the tolerable regenerative power (W).

- The regenerative braking frequency of the 600W or smaller servo amplifier may fluctuate due to the affect of the power voltage since the energy charged by the electrolytic capacitor in the servo amplifier is large.

- There are no limits on regeneration frequency as long as the effective torque is within the rated torque range. However, the load/motor of inertia moment ratio must be 15 times or less.

- Contact Mitsubishi if the load/motor of inertia moment ratio exceeds the value in the table.

- The shaft-through portion and connector for cable terminal are excluded.

- The vibration direction is shown in the right-side diagram. The numeric value indicates the maximum value of the component (commonly the bracket in the opposite direction of the motor shaft). Fretting of the bearing occurs easily when the motor stops, so maintain vibration to approximately one-half of the allowable value.

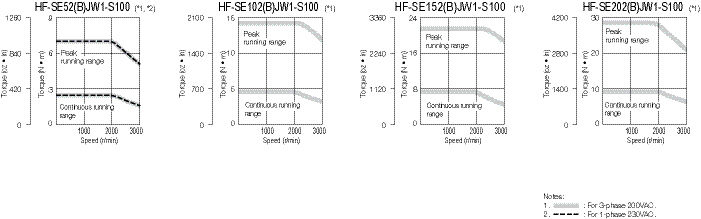

MR-E HF-SE Super 2000 r/min Series Servomotor Specifications

|

Servomotor Model |

HF-SE52JW1-S100 |

HF-SE102JW1-S100 |

HF-SE152JW1-S100 |

HF-SE202JW1-S100 | ||

|

Servomotor Model With Brake |

HF-SE52BJW1-S100 |

HF-SE102BJW1-S100 |

HF-SE152BJW1-S100 |

HF-SE202BJW1-S100 | ||

|

Compatible Servo Amplifier Model |

MR-E-70A-KH003 |

MR-E-100A-KH003 |

MR-E-200A-KH003 | |||

|

Compatible Servo Amplifier with Analog Input Interface |

MR-E-70AG-KH003 |

MR-E-100AG-KH003 |

MR-E-200AG-KH003 | |||

|

Power Facility Capacity (kVA) (*1) |

1.0 |

1.7 |

2.5 |

3.5 | ||

|

Continuous Running Duty |

Rated Output (kW) |

0.5 |

1.0 |

1.5 |

2.0 | |

|

Rated Torque (N·m [oz•in]) |

2.39 (338) |

4.77 (675) |

7.16 (1010) |

9.55 (1350) | ||

|

Maximum Torque (N•m [oz•in]) |

7.16 (1010) |

14.3 (2020) |

21.5 (3040) |

28.6 (4050) | ||

|

Rated Speed (r/min) |

2000 | |||||

|

Maximum Speed (r/min) |

3000 | |||||

|

Permissible Instantaneous Speed (r/min) |

3450 | |||||

|

Power Rate At Continuous Rated Torque (kW/s) |

9.34 |

19.2 |

28.8 |

23.8 | ||

|

Rated Current (A) |

2.9 |

5.3 |

8.0 |

10 | ||

|

Maximum Current (A) |

8.7 |

15.9 |

24 |

30 | ||

|

Regenerative Braking Frequency (Times / Min) (*2, *3) |

With No Options |

120 |

62 |

152 |

71 | |

|

MR-RB032 (30W) |

180 |

93 |

- |

- | ||

|

MR-RB12 (100W) |

600 |

310 |

- |

- | ||

|

MR-RB30 (300W) |

- |

- |

456 |

213 | ||

|

MR-RB32 (300W) |

1800 |

930 |

- |

- | ||

|

MR-RB50 (500W) |

- |

- |

760 |

355 | ||

|

Moment Of Inertia J (x10-4 kg • m²) [J (oz • in²)] |

Standard |

6.1 (33.4) |

11.9 (65.1) |

17.8 (97.3) |

38.3 (209) | |

|

With Electromagnetic Brake |

8.3 (45.4) |

14.0 (76.5) |

20.0 (109) |

47.9 (262) | ||

|

Recommended Load / Motor Inertia Moment Ratio |

Maximum of 15 times the servomotor’s inertia moment (*4) | |||||

|

Speed / Position Detector |

Incremental encoder (resolution per servomotor: 131072 p/rev) | |||||

|

Attachments |

Oil seal | |||||

|

Structure |

Totally enclosed non ventilated (protection level: IP65) (*5) | |||||

|

Environment |

Ambient Temperature |

0 to 40°C (32 to 104°F) (non-freezing), storage: -15 to 70°C (5 to 158°F) (non-freezing) | ||||

|

Ambient Humidity |

80% RH maximum (non-condensing), storage: 90% RH maximum (non-condensing) | |||||

|

Atmosphere |

Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist or dust | |||||

|

Elevation |

1000m or less above sea level | |||||

|

Vibration (*6) |

X, Y: 24.5m/s² |

X: 24.5m/s² • Y: 49m/s² | ||||

|

Weight kg (lb) |

Standard |

4.8 (11) |

6.5 (15) |

8.3 (19) |

12 (27) | |

|

With Electromagnetic Brake |

6.7 (15) |

8.5 (19) |

11 (25) |

18 (40) | ||

Notes:

- The power facility capacity varies depending on the power supply’s impedance

- The regenerative braking frequency shows the permissible frequency when the motor, without a load and the optional regeneration unit, decelerates from the rated speed to a stop. When a load is connected; however, the value will be the table value/(m+1), where m=the load inertia moment/the motor inertia moment. When the operating speed exceeds the rated speed, the regenerative braking frequency is inversely proportional to the square of (operating speed/rated speed). If the operating speed changes frequently or when the regeneration is constant (as with vertical feeds), find the regenerative heating value (W) in operation. Provisions must be made to keep this heating value below the tolerable regenerative power (W). Optimal regenerative resistor varies for each system. Refer to the section “Optional Accessories • Regenerative Brake Options” in this catalog for details on the tolerable regenerative power (W).

- The regenerative braking frequency of the 600W or smaller servo amplifier may fluctuate due to the affect of the power voltage since the energy charged by the electrolytic capacitor in the servo amplifier is large

- Contact Mitsubishi if the load/motor of inertia moment ratio exceeds the value in the table

- The shaft-through portion is excluded.

- The vibration direction is shown in the right-side diagram. The numeric value indicates the maximum value of the component (commonly the bracket in the opposite direction of the motor shaft). Fretting of the bearing occurs easily when the motor stops, so maintain vibration to approximately one-half of the allowable value.

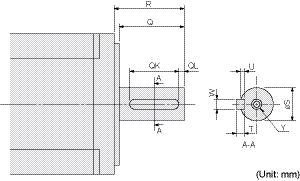

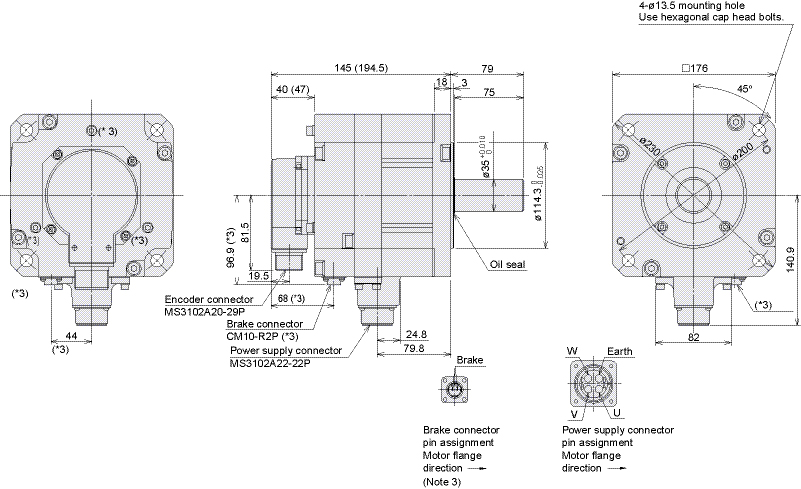

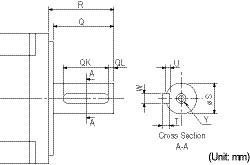

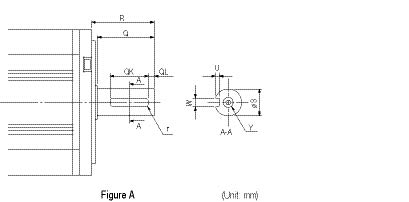

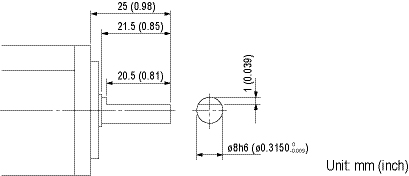

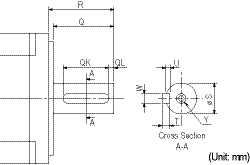

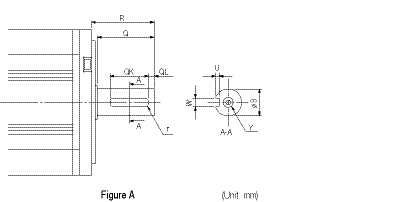

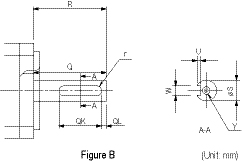

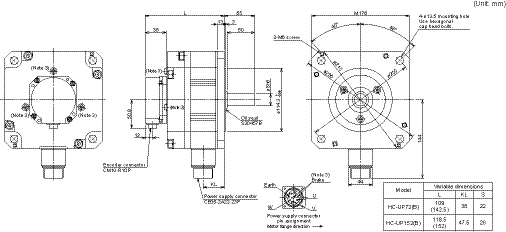

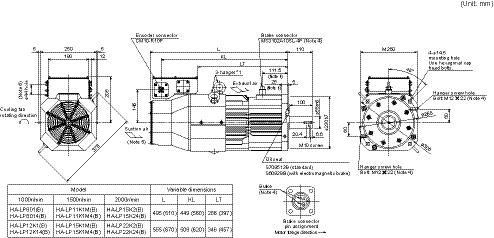

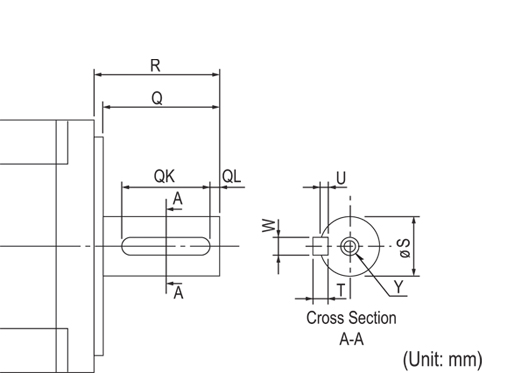

MR-E Super Shaft Detail

HF-KE_(B)W1-S100: With key (200, 400, 750W)

|

Model Number (*1) |

Variable Dimensions | ||||||||

|

T |

S |

R |

Q |

W |

QK |

QL |

U |

Y | |

|

HF-KE23(B)KW1-S100

|

5 |

14h6 |

30 |

27 |

5 |

20 |

3 |

3 |

M4 screw Depth: 15mm |

|

HF-KE73(B)KW1-S100 |

6 |

19h6 |

40 |

37 |

6 |

25 |

5 |

3.5 |

M5 screw Depth: 20mm |

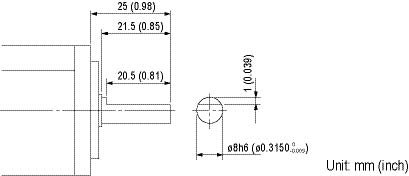

HF-KE13(B)DW1-S100: D-cut (100W) (*1)

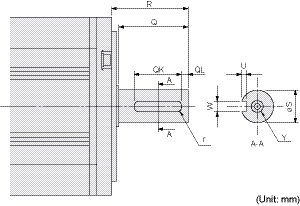

HF-SE_(B)JW1-S100: Key way - Key not included

|

Model Number (*1, *2) |

Variable Dimensions | ||||||||

|

S |

R |

Q |

W |

QK |

QL |

U |

r |

Y | |

|

HF-SE52(B)JKW1-S100

|

24h6 |

55 |

50 |

8 |

36 |

5 |

4 |

4 |

M8 screw Depth: 20mm |

|

HF-SE202(B)JKW1-S100 |

35 |

79 |

75 |

10 |

55 |

5 |

5 |

5 |

M8 screw Depth: 20mm |

Notes:

- Motors with keyway shaft (with/without key) and D-cut shaft cannot be used in frequent start/stop applications. Loose keys may damage the motor shaft.

- A key is not supplied with the motor. The key shall be installed by the user.

Optional Keys Available (Order Separately)

|

Motor Model |

Model Number |

Key Dimensions |

Stocked Item |

|

HF-SE52~152(B)JKW1-S100 |

MTR KEY 8-7-28 |

8 x 7 x 28 |

S |

|

HF-SE202(B)JKW1-S100 |

MTR KEY 10-8-45 |

10 x 8 x 45 |

S |

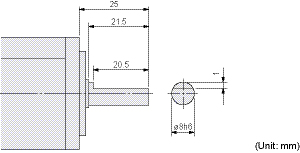

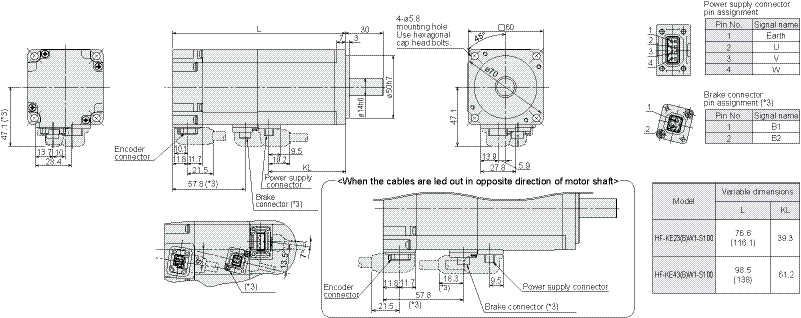

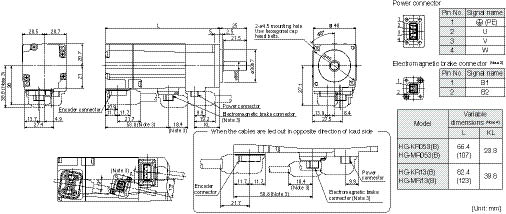

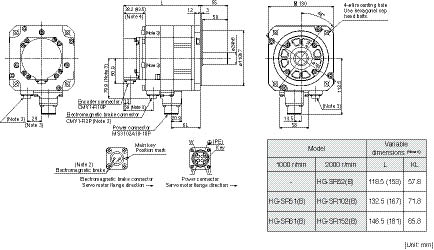

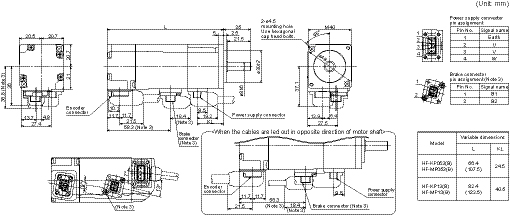

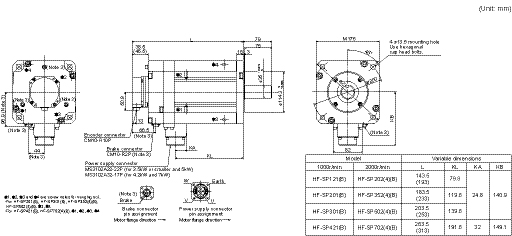

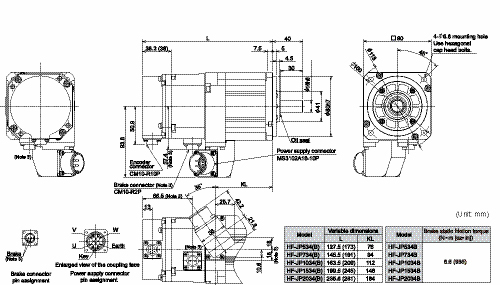

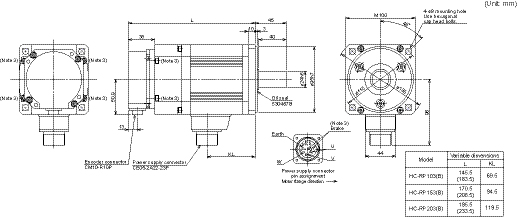

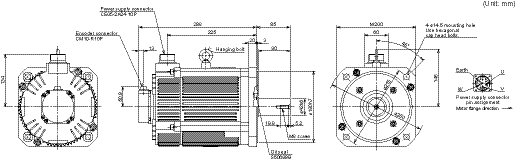

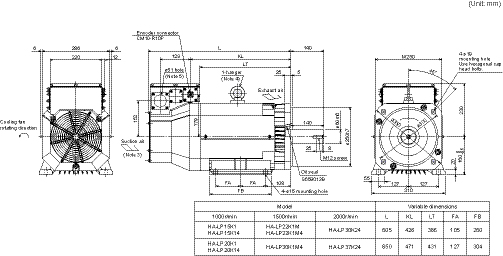

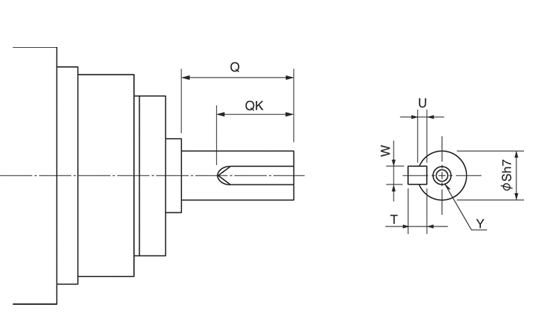

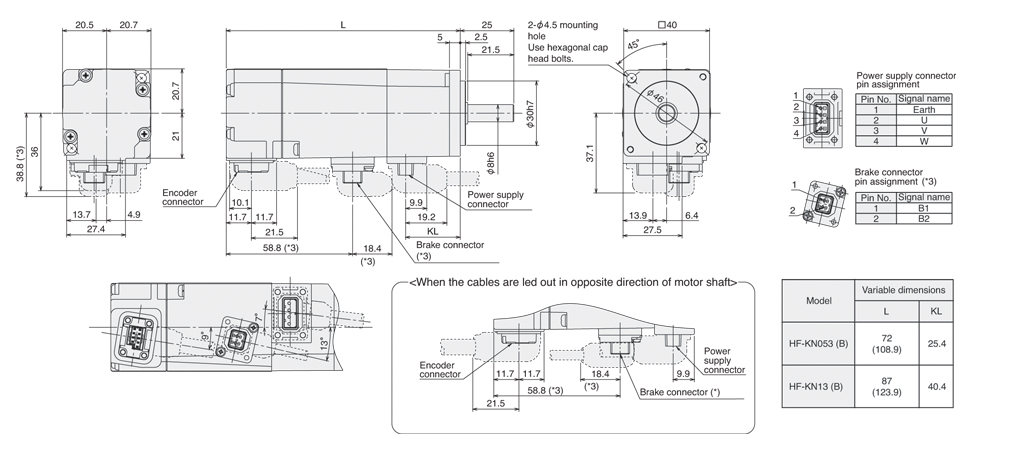

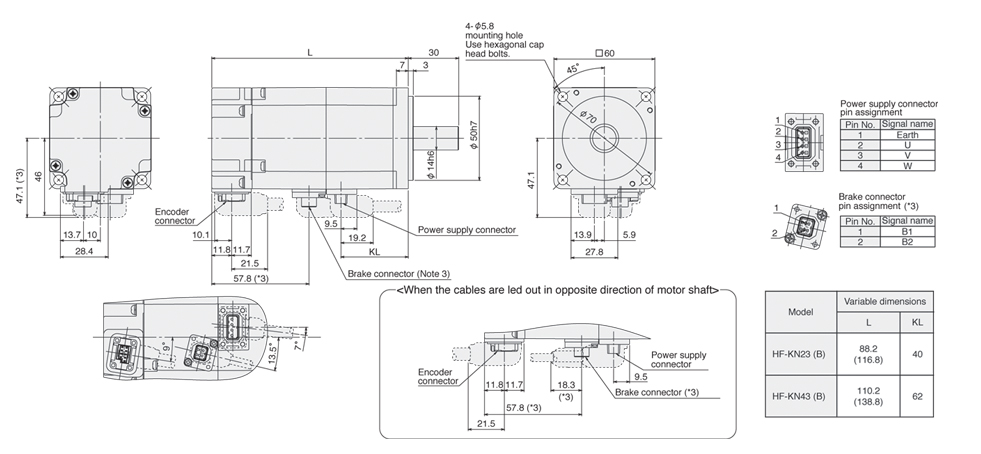

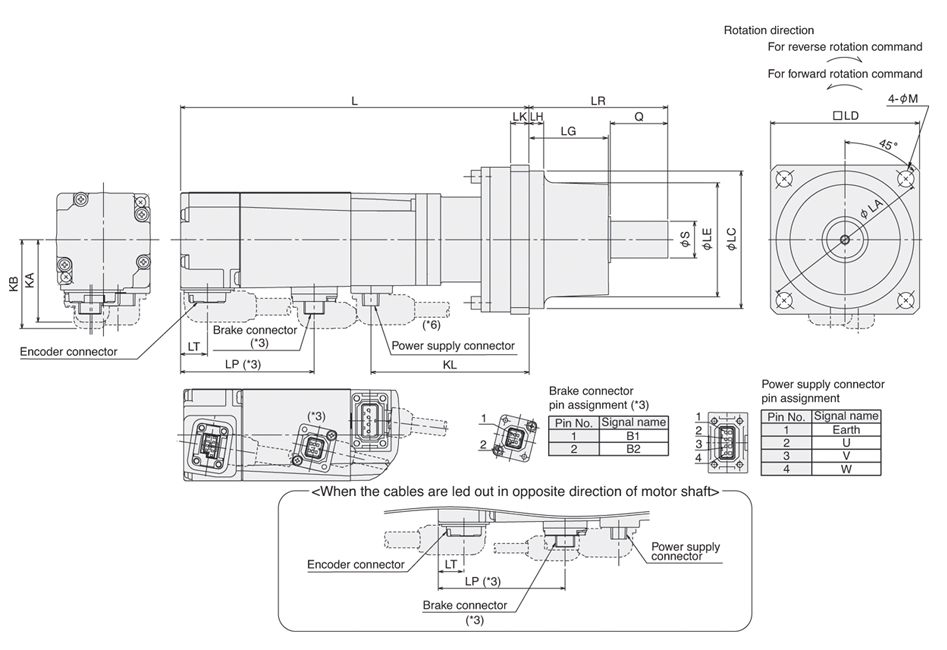

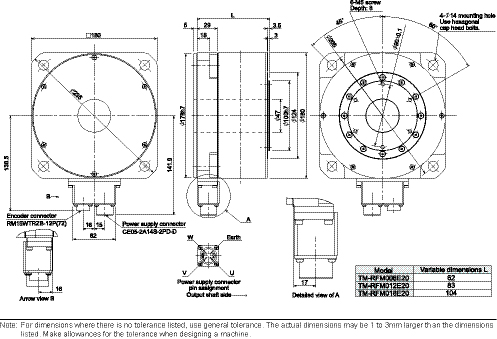

HF-KE Super Series

HF-KE13(B)W1-S100

HF-KE23(B)W1-S100, HF-KE43(B)W1-S100

HF-KE73(B)W1-S100

Notes:

- Use a friction coupling to fasten a load.

- Dimensions inside ( ) are for the models with an electromagnetic brake.

- Only for the models with an electromagnetic brake. The electromagnetic brake terminals (B1, B2) do not have polarity.

- For dimensions where there is no tolerance listed, use general tolerance.

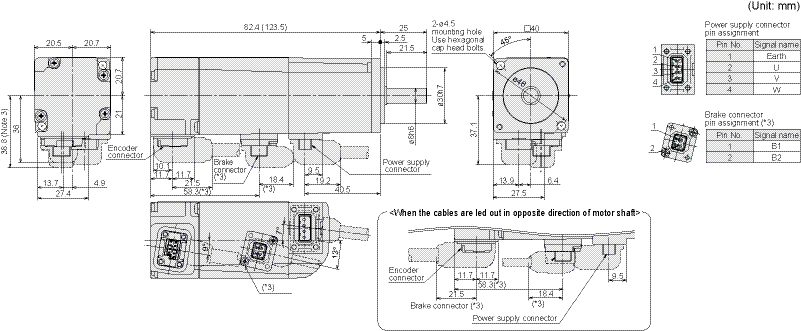

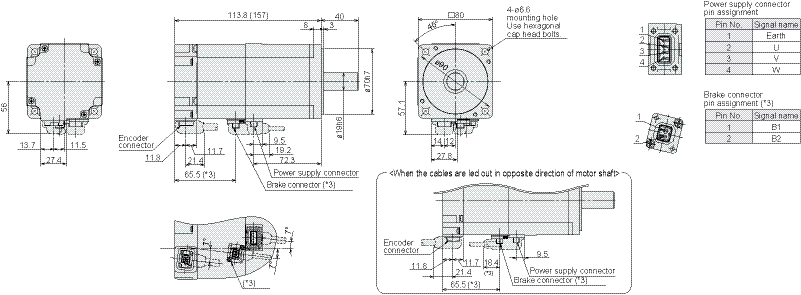

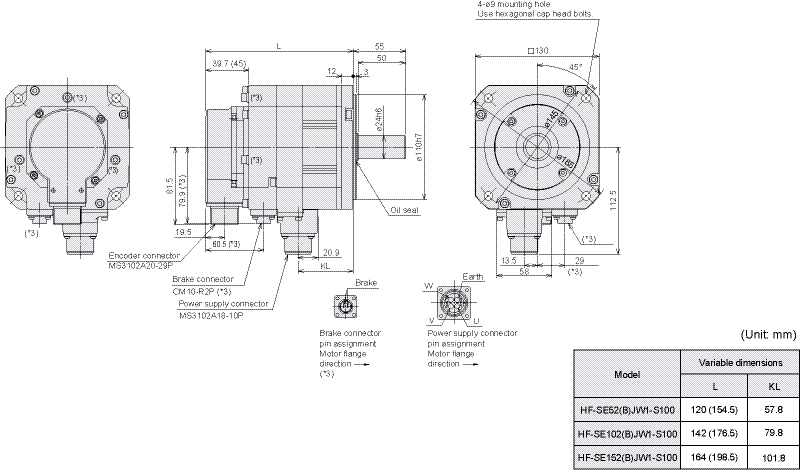

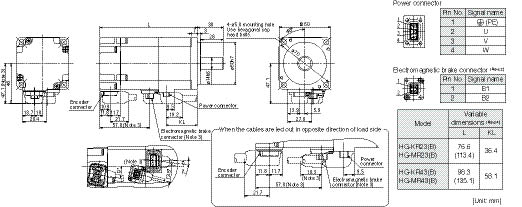

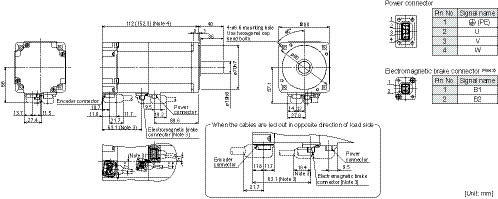

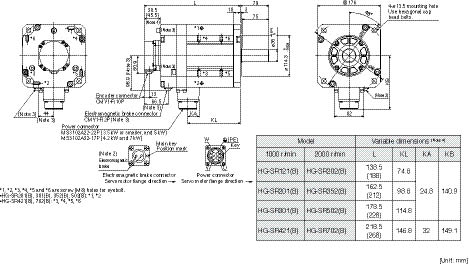

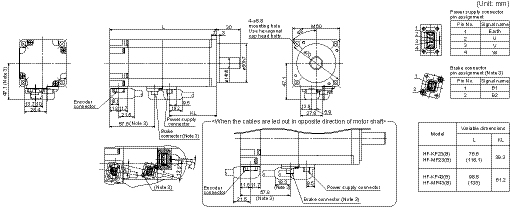

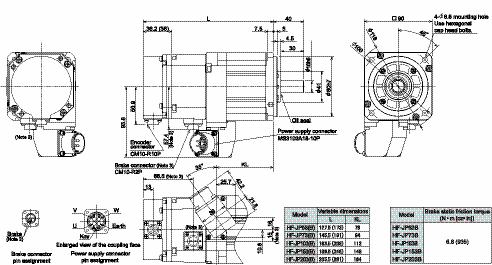

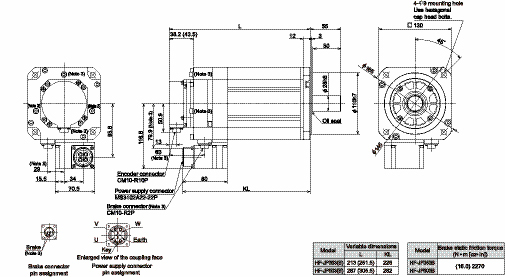

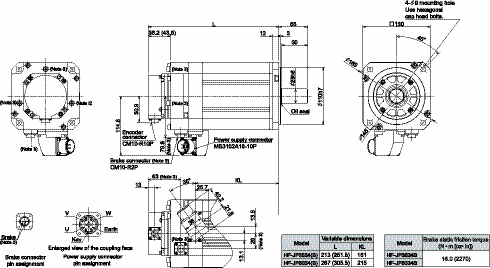

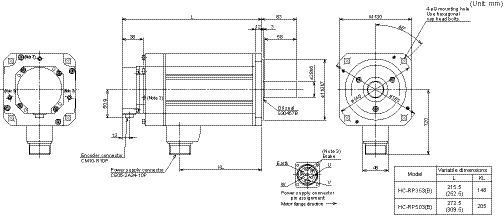

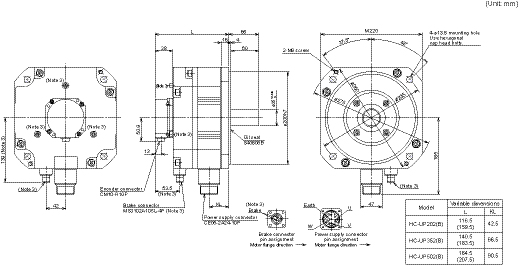

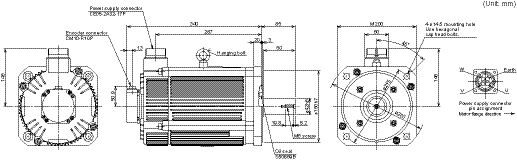

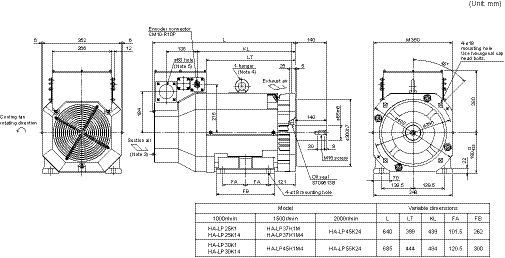

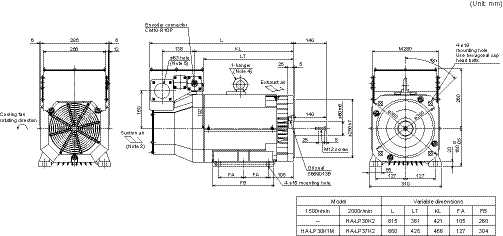

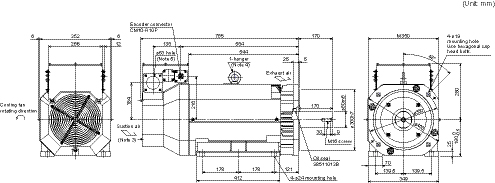

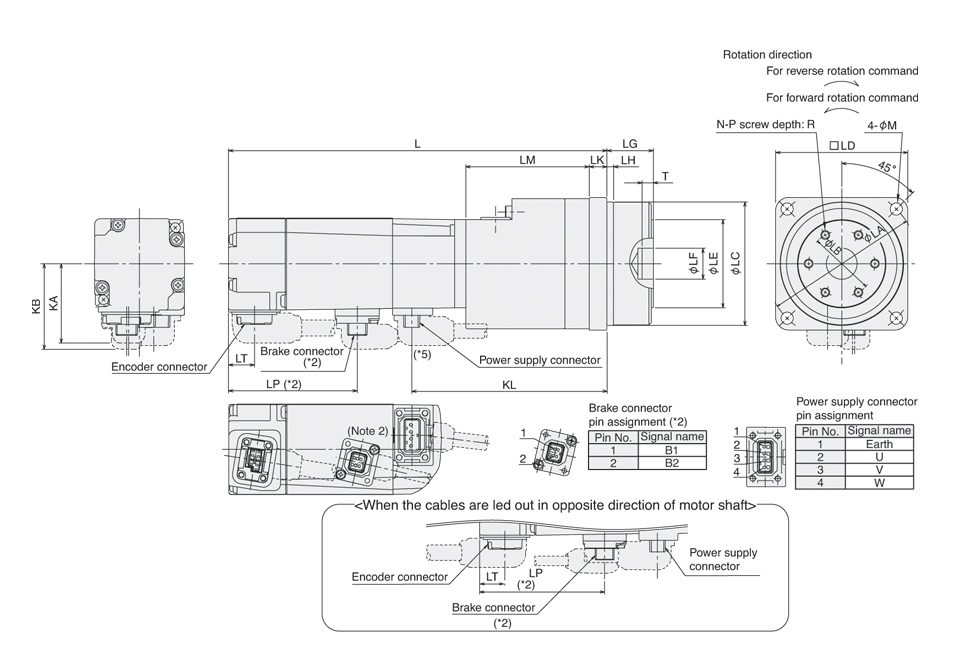

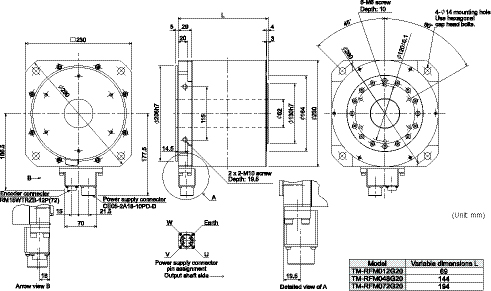

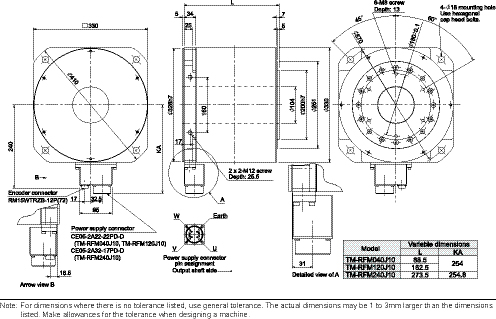

HF-SE Super Series

HF-SE52(B)JW1-S100, HF-SE102(B)JW1-S100, HF-SE152(B)JW1-S100

HF-SE202(B)JW1-S100

Notes:

- Use a friction coupling to fasten a load.

- Dimensions inside ( ) are for the models with an electromagnetic brake.

- Only for the models with an electromagnetic brake. The electromagnetic brake terminals do not have polarity.

- For dimensions where there is no tolerance listed, use general tolerance.

Amplifier Selection

Servo Standard Specifications

|

Servo Amplifier Model |

MR-E-10A-KH003 |

MR-E-20A-KH003 |

MR-E-40A-KH003 |

MR-E-70A-KH003 |

MR-E-100A-KH003 |

MR-E-200A-KH003 | ||

|

MR-E-10AG-KH003 |

MR-E-20AG-KH003 |

MR-E-40AG-KH003 |

MR-E-70AG-KH003 |

MR-E-100AG-KH003 |

MR-E-200AG-KH003 | |||

|

Stocked Item |

S |

S |

S |

S |

S |

S | ||

|

Power Supply |

Voltage/Frequency (*1) |

3-phase 200 to 230VAC 50/60Hz or 1-phase 230VAC 50/60Hz |

3-phase 200 to 230VAC 50/60Hz | |||||

|

Permissible Voltage Fluctuation |

For 3-phase 200 to 230VAC: 3-phase 170 to 253VAC

|

3-phase 170 to 253VAC | ||||||

|

Permissible Frequency Fluctuation |

±5% maximum | |||||||

|

Control System |

Sine-wave PWM control/current control system | |||||||

|

Dynamic Brake |

Built-in | |||||||

|

Built-In Regenerative Resistor |

None |

Installed | ||||||

|

Safety Features |

Overcurrent shutdown, regeneration overvoltage shutdown, overload shutdown (electronic thermal), encoder fault protection,

| |||||||

|

A Type Amps |

Position Control Mode |

Maximum Input Pulse Frequency |

1Mpps (when using differential receiver), 200 kpps (when using open collector) | |||||

|

Positioning Feedback Pulse |

Resolution per encoder/servomotor rotation: 131072 p/rev | |||||||

|

Command Pulse Multiple |

Electronic gear A/B multiple, A: 1 to 65535, B: 1 to 65535, 1/50 < A/B < 50 | |||||||

|

Positioning Complete Width Setting |

0 to ±10000 pulses (command pulse unit) | |||||||

|

Excess Error |

±2.5 rotations | |||||||

|

Torque Limit |

Set by parameters | |||||||

|

Speed Control Mode |

Speed Control Range |

Internal speed command 1:5000 | ||||||

|

Speed Fluctuation Rate |

±0.01% maximum (load fluctuation 0 to 100%) 0% (power fluctuation ±10%) | |||||||

|

Torque Limit |

Set by parameters | |||||||

|

AG Type Amps |

Speed Control Mode |

Speed Control Range |

Analog speed command 1:2000, internal speed command 1:5000 | |||||

|

Analog Speed Command Input |

0 to ±10VDC / rated speed | |||||||

|

Speed Fluctuation Rate |

±0.01% maximum (load fluctuation 0 to 100%); 0% (power fluctuation ±10%)

| |||||||

|

Torque Limit |

Set by parameters or external analog input (0 to +10VDC/maximum torque) | |||||||

|

Torque Control Mode |

Analog Torque Command Input |

0 to ±8VDC/maximum torque (input impedance 10 to 12kΩ) | ||||||

|

Speed Limit |

Set by parameters or external analog input (0 to ±10VDC/rated speed) | |||||||

|

Structure |

Self-cooling open (IP00) |

Fan cooling open (IP00) | ||||||

|

Environment |

Ambient Temperature |

0 to 55°C (32 to 131°F) (non-freezing), storage: -20 to 65°C (-4 to 149°F) (non-freezing) | ||||||

|

Ambient Humidity |

90% RH maximum (non-condensing), storage: 90% RH maximum (non-condensing) | |||||||

|

Atmosphere |

Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist or dust | |||||||

|

Elevation |

1000m or less above sea level | |||||||

|

Vibration |

5.9m/s² maximum | |||||||

|

Weight kg (lb) |

0.7 (1.5) |

0.7 (1.5) |

1.1 (2.4) |

1.7 (3.7) |

1.7 (3.7) |

2.0 (4.4) | ||

Note:

- Rated output and rated speed of a servomotor are applicable when the servo amplifier, combined with the servomotor, is operated within the specified power supply voltage and frequency. The torque drops when the power supply voltage is less than specified.

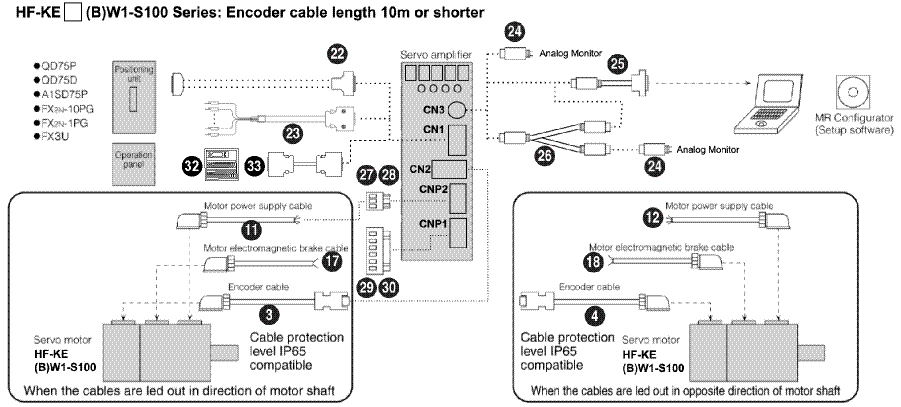

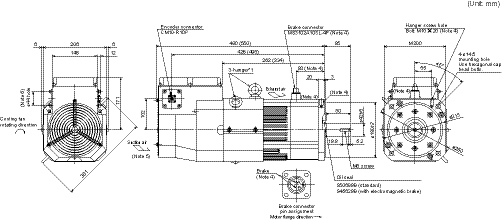

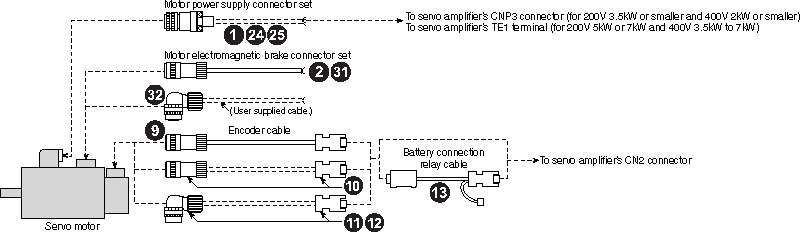

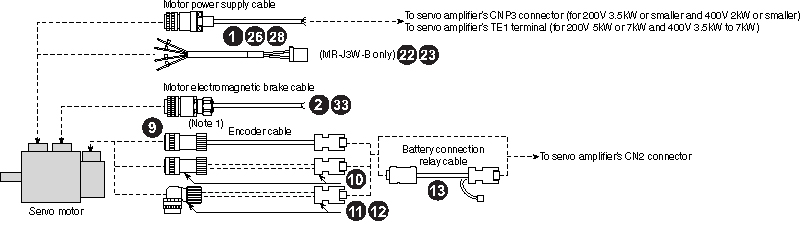

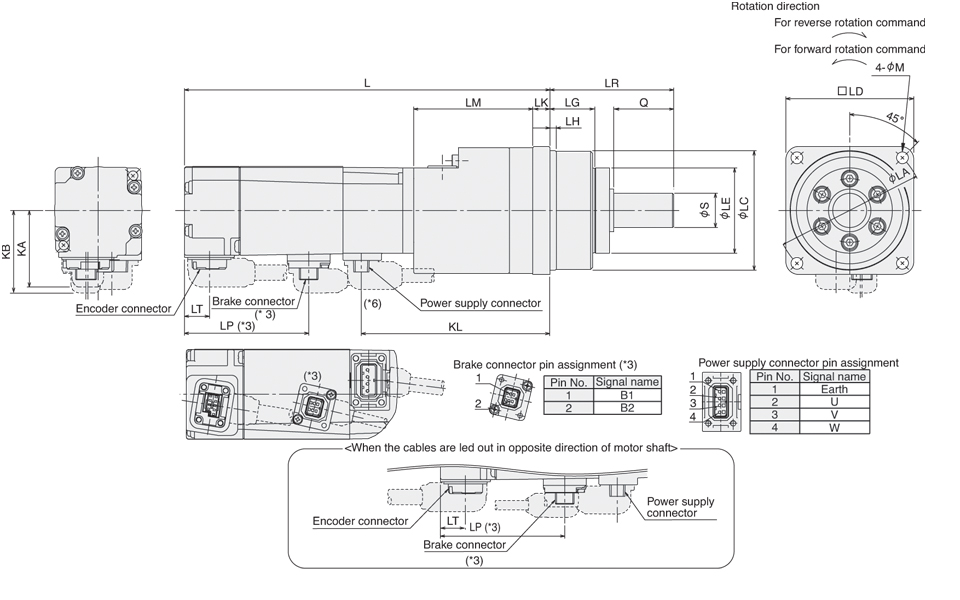

HF-KE_(B)W1-S100 Series: Encoder cable length 10m or shorter

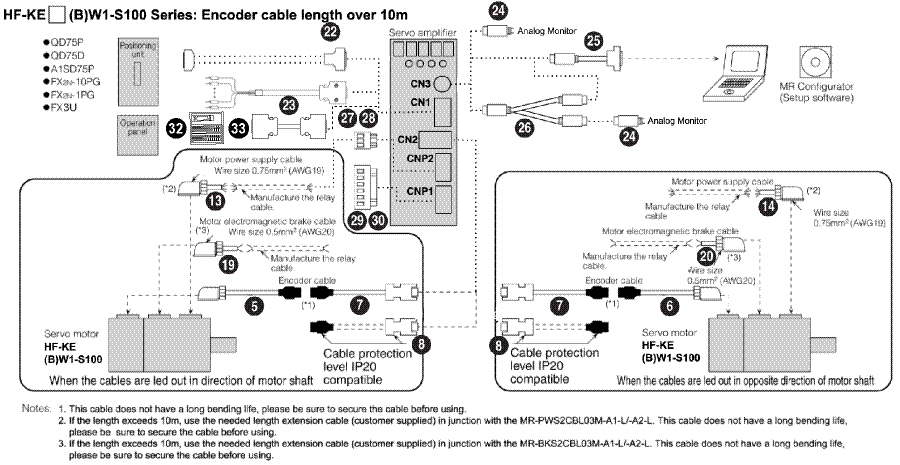

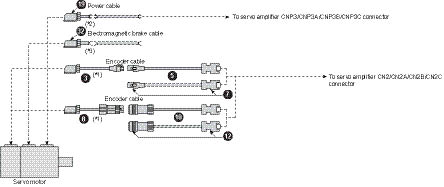

HF-KE_(B)W1-S100 Series: Encoder cable length over 10m

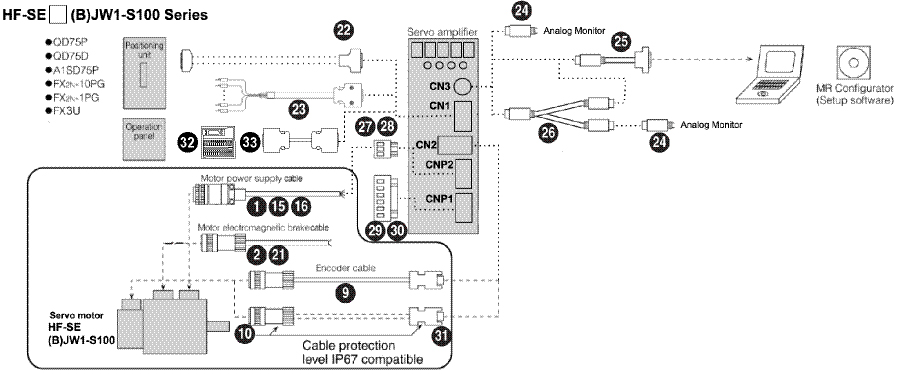

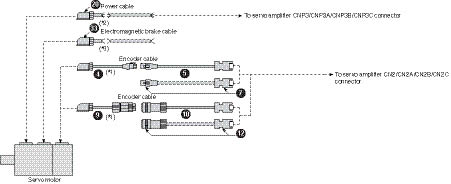

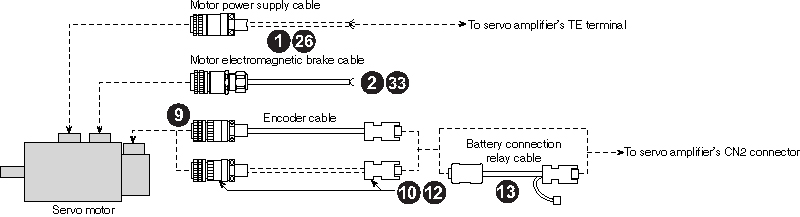

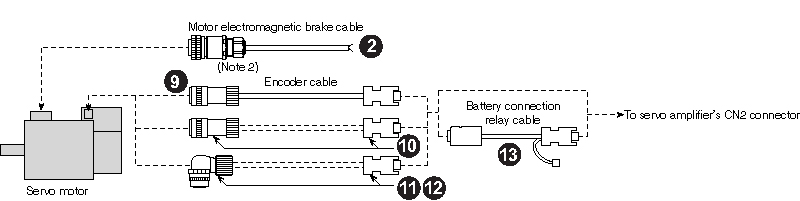

HF-SE_(B)JW1-S100 Series

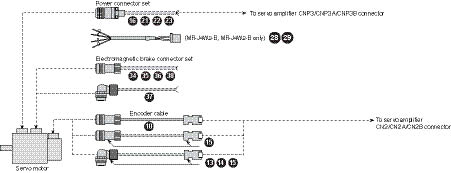

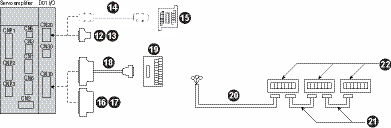

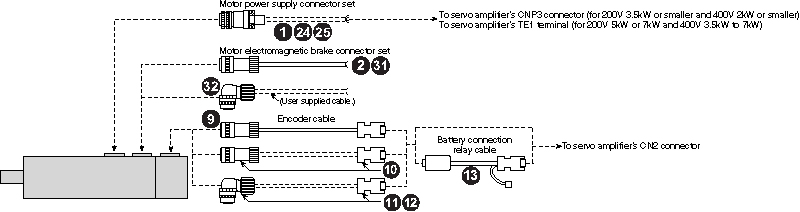

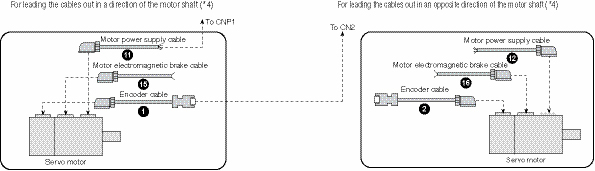

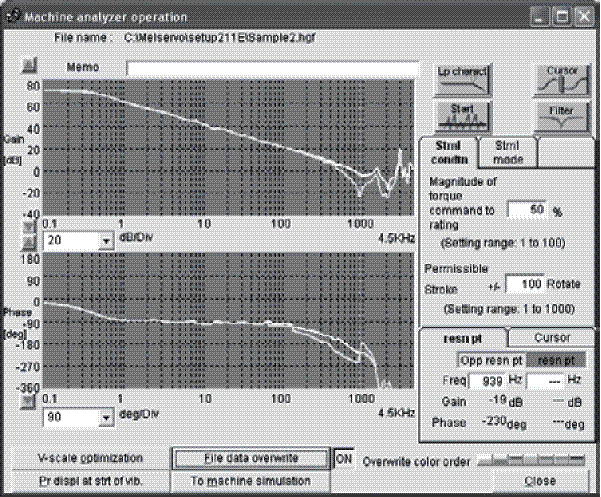

MR-E Super Cables and Connectors (refer to charts above)

Power Cables for HF-SE_(B)JW1-S100

|

Item |

Model Number

|

Stocked Lengths |

Protection Level |

Diagram | ||

|

|

Standard-Flex, Unshielded Type Cables (Straight Type Connector Only) |

HF-SE52(B)JW1-S100 (*1) |

MR-J3P1-_M (*2) |

2, 5, 10, 20, 30 |

IP65 |

|

|

HF-SE102(B)JW1-S100 (*1) |

MR-J3P2-_M (*2) | |||||

|

HF-SE152(B)JW1-S100 (*1) |

MR-J3P2-_M (*2) | |||||

|

HF-SE202(B)JW1-S100 (*1) |

MR-J3P4-_M (*2) | |||||

|

High-Flex, Shielded Type Cables (Straight Type Connector Only) |

HF-SE52(B)JW1-S100 (*1) |

MR-J3PWS1-_M (*2) |

2, 5, 10, 20, 30 |

IP67 |

| |

|

HF-SE102(B)JW1-S100 (*1) |

MR-J3PWS2-_M (*2) | |||||

|

HF-SE152(B)JW1-S100 (*1) |

MR-J3PWS2-_M (*2) | |||||

|

HF-SE202(B)JW1-S100 (*1) |

MR-J3PWS4-_M (*2) | |||||

Brake Cables for HF-SE_BJW1-S100

|

Item |

Model Number

|

Stocked Lengths |

Protection Level |

Diagram | |

|

|

Standard-Flex, Unshielded Type Cables |

MR-J3BK-_M |

2, 5, 10, 20, 30 |

IP65 |

|

|

High-Flex, Shielded Type Cables |

MR-J3BRKS1-_M |

2, 5, 10, 15, 20, 30 |

IP65 |

| |

Encoder Cables for CN2 Connector for HF-KE_(B)W1-S100

|

Item |

Model Number

|

Stocked Lengths |

Protection Level |

Diagram | ||

|

|

10m or Shorter (Direct Connection Type) |

Lead Out in Direction of Motor Shaft |

MR-J3ENCBL_M-A1-H

|

2, 5, 10 |

IP65 |

|

|

MR-J3ENCBL_M-A1-L

|

2, 5, 10 |

IP65 | ||||

|

|

Lead Out in Opposite Direction of Motor Shaft |

MR-J3ENCBL_M-A2-H

|

2, 5, 10 |

IP65 | ||

|

MR-J3ENCBL_M-A2-L

|

2, 5, 10 |

IP65 | ||||

|

|

Exceeding 10m (Relay Type) |

Lead Out in Direction of Motor Shaft |

MR-J3JCBL03M-A1-L

|

S |

IP20 |

|

|

|

Lead Out in Opposite Direction of Motor Shaft |

MR-J3JCBL03M-A2-L

|

S |

IP20 | ||

|

|

Amplifier-Side Cable |

MR-EKCBL_M-H _= 20, 30, 40, or 50 (*1) |

20, 30 |

IP20 |

| |

|

MR-EKCBL_M-L _= 20 or 30 (*1) |

- |

IP20 | ||||

|

|

Junction Connector, Amplifier-Side Connector |

MR-ECNM |

S |

IP20 |

| |

Encoder Cable for CN2 Connector for HF-SE_(B)JW1-S100

|

Item |

Model Number

|

Stocked Lengths |

Protection Level |

Diagram | |

|

|

Encoder Cable |

MR-ENECBL_M-H

|

2, 5, 10 |

IP67 |

|

|

|

Encoder Connector Set |

MR-ENECNS |

S |

IP67 |

|

Motor Power Supply Cables for CNP2 for HF-KE_(B)W1-S100

|

Item |

Model Number

|

Stocked Lengths |

Protection Level |

Diagram | ||

|

|

10m or Shorter (Direct Connection Type) |

Lead Out in Direction of Motor Shaft (Non-shielded) |

MR-PWS1CBL_M-A1-H

|

2, 5, 10 |

IP65 |

|

|

MR-PWS1CBL_M-A1-L

|

2, 5, 10 |

IP65 | ||||

|

Lead Out in Direction of Motor Shaft (Shielded) |

MR-J3PS_M-A1

|

5 |

IP65 | |||

|

|

Lead Out in Opposite Direction of Motor Shaft (Non-shielded) |

MR-PWS1CBL_M-A2-H

|

2, 5, 10 |

IP65 | ||

|

MR-PWS1CBL_M-A2-L

|

2, 5, 10 |

IP65 | ||||

|

Lead Out in Opposite Direction of Motor Shaft (Shielded) |

MR-J3PS_M-A2

|

5, 10 |

IP65 | |||

|

|

Exceeding 10m (Relay Type) |

Lead Out in Direction of Motor Shaft (Non-shielded) |

MR-PWS2CBL03M-A1-L

|

S |

IP55 |

|

|

Lead Out in Direction of Motor Shaft (Shielded) |

MR-J3PS03M-A1

|

S |

IP65 | |||

|

|

Lead Out in Opposite Direction of Motor Shaft (Non-shielded) |

MR-PWS2CBL03M-A2-L

|

S |

IP55 | ||

|

Lead Out in Opposite Direction of Motor Shaft (Shielded) |

MR-J3PS03M-A2

|

S |

IP65 | |||

Notes:

- Must order separate brake cable for these motors.

- Must order separate power connector 27 or 28 to connect to the power cable.

Power Supply Connectors

|

Item |

Model Number |

Stocked Item |

Protection Level |

Diagram | |

|

|

Motors: HF-SE52(B)JW1-S100; HF-SE102(B)JW1-S100; HF-SE152(B)JW1-S100 (see |

MR-PWCNS4 (straight type only) |

S |

IP67 |

|

|

|

Motor: HF-SE202(B)JW1-S100 (see |

MR-PWCNS5 (straight type only) |

S |

IP67 |

|

Motor Brake Cables for HF-KE_BW1-S100

|

Item |

Model Number

|

Stocked Lengths |

Protection Level |

Diagram | ||

|

|

10m or Shorter (Direct Connection Type) |

Lead Out in Direction of Motor Shaft |

MR-BKS1CBL_M-A1-H _= 2, 5, or 10 (*1) |

2, 5, 10 |

IP65 |

|

|

MR-BKS1CBL_M-A1-L _= 2, 5, or 10 (*1) |

- |

IP65 | ||||

|

|

Lead Out in Opposite Direction of Motor Shaft |

MR-BKS1CBL_M-A2-H _= 2, 5, or 10 (*1) |

2, 5, 10 |

IP65 | ||

|

MR-BKS1CBL_M-A2-L _= 2, 5, or 10 (*1) |

- |

IP65 | ||||

|

|

Exceeding 10m (Relay Type) |

Lead Out in Direction of Motor Shaft |

MR-BKS2CBL03M-A1-L cable length 0.3 (*1) |

S |

IP55 |

|

|

|

Lead Out in Opposite Direction of Motor Shaft |

MR-BKS2CBL03M-A2-L cable length 0.3 (*1) |

S |

IP55 | ||

Note:

- -H and -L indicate bending life. -H indicates a long bending life and -L indicates a standard bending life.

Brake Connector Set for HF-SE_BJW1-S100

|

Item |

Model Number |

Stocked Item |

Protection Level |

Diagram | |

|

|

Brake Connector (see |

MR-BKCNS1 (straight type only) |

S |

IP67 |

|

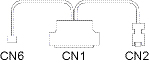

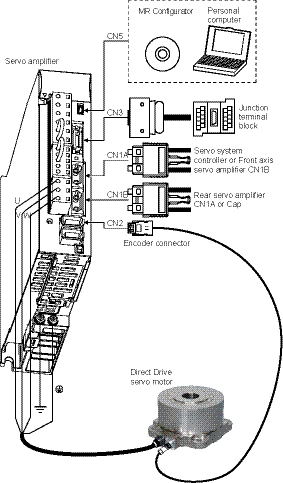

Connector for CN1 on Amp

|

Item |

Model Number |

Stocked Item |

Protection Level |

Diagram | |

|

|

CN1 Connector (26 pin) |

MR-ECN1 |

S |

- |

|

Pigtail Cable for CN1 on Amp

|

Item |

Model Number |

Stocked Item |

Protection Level |

Diagram | |

|

|

CN1 Pigtail Cable (26 pin) |

MR-ECN1CBL-3M (3 meter cable) |

S |

- |

|

Connector and Cable Options for CN3 Connector on Amp

|

Item |

Model Number |

Stocked Lengths |

Protection Level |

Diagram | |

|

|

Analog Monitor RS-232C Connector |

MR-ECN3 |

S |

- |

|

|

|

Communication Cable |

SC-Q (3 meter cable) |

S |

- |

|

|

|

Analog Monitor RS-232C Branch Cable |

MR-E3CBL15-P |

S |

- |

|

CNP2 Power to Motor Connector

|

Item |

Model Number |

Stocked Item |

Protection Level |

Diagram | |

|

|

MR-E10 to 100A/AG-KH003 |

MR-ECNP2-B |

S |

- |

|

|

|

MR-E200A/AG-KH003 Amp Only |

MR-ECNP2-B1 |

S |

- | |

CNP1 Amp Power Input Connector

|

Item |

Model Number |

Stocked Item |

Protection Level |

Diagram | |

|

|

MR-E10 to 100A/AG-KH003 Amps |

MR-ECNP1-B |

S |

- |

|

|

|

MR-E200A/AG-KH003 Amp Only |

MR-ECNP1-B1 |

S |

- | |

CN2 Connector

|

Item |

Model Number |

Stocked Item |

Protection Level |

Diagram | |

|

|

CN2 Connector Only |

MR-J3CN2 |

S |

- |

|

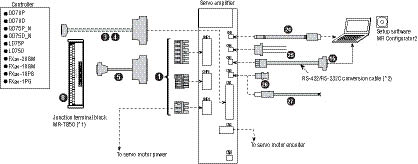

For CN1

|

Item |

Model Number |

Stocked Lengths |

Protection Level |

Diagram | |

|

|

Junction Terminal Block |

MR-TB26A |

S |

- |

|

|

|

Junction Terminal Block Cable |

MR-TBNATBL_M (_ =cable length: 0.5, 1m) |

05, 1 |

- |

|

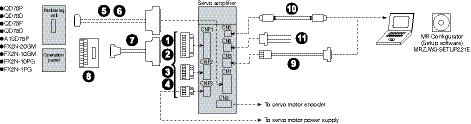

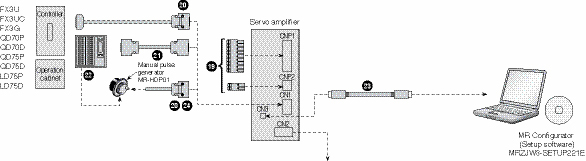

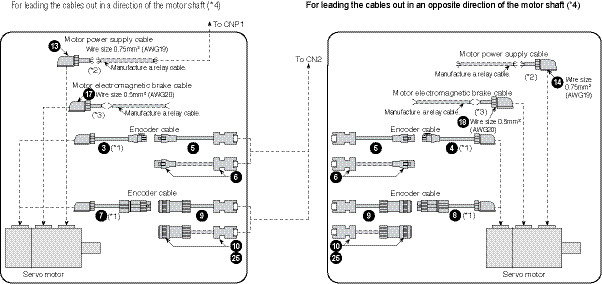

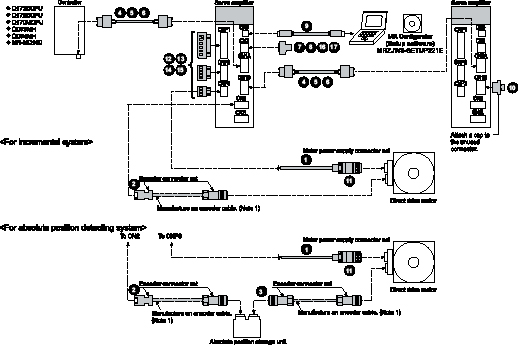

Software and Manuals

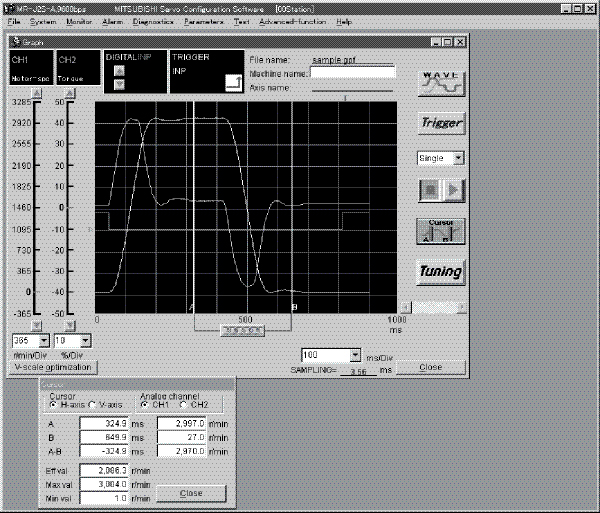

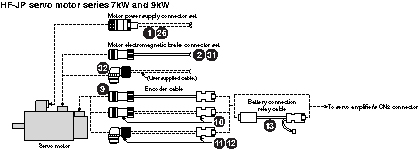

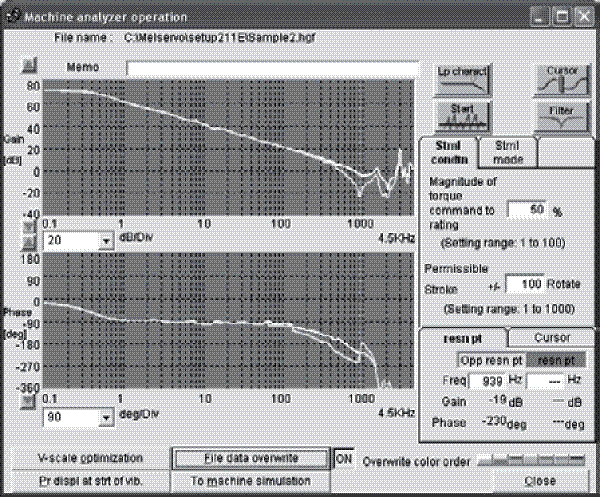

MR-Configurator Setup Software

This Windows® based software package is used to setup, program and test the amplifier. Initial setup and programming is easy and quick with the user-friendly software, which has extensive help functions and drop-downs. MR-Configurator also has many diagnostic functions such as a machine simulator to aid in mechanical design, a machine analyzer to find resonant frequencies of the load and set notch filters, an alarm monitor with history data, and the ability to assign and monitor I/O.

Features:

- Can be set up using a personal computer. Works on Windows 95/98/NT/ME/2000 Professional, XP Professional*.

- Provides numerous monitor functions. Provides graph display function that enables display of servomotor status upon input signal triggers such as command pulses, droop pulses, and r/min.

- Allows servomotors to be tested easily from a personal computer.

* Windows is a registered trademark of the Microsoft Corporation.

|

Description |

Model Number |

Stocked Item |

|

Windows Communication Software |

MR-CONFIGURATOR |

S |

|

Communications Cable |

SC-Q |

S |

Manuals

|

Hardware Description |

Model Number |

Stocked Item |

|

MR-E Super |

SH(NA)030071 |

MEAU.com |

|

EMC Guidelines (Servo) Manual |

IB(NA)67310 |

MEAU.com |

Note: Many of these manuals are available for free download from our website, www.meau.com

Optional Accessories

Filters

|

Description |

Model Type |

Model Number |

Stocked Item |

|

Line Noise Filter |

All MR-E Models |

FR-BSF01 |

S |

|

Radio Noise Filter |

All MR-E Models |

FR-BIF |

S |

|

EMC Filter |

MR-E-10 to 100 |

SF1252 |

S |

|

EMC Filter |

MR-E-200 |

MF-3F480-025.230 |

- |

Regenerative Brake Options

|

Servo Amplifier |

Model Number - Regenerative Power [W] | |||||

|

Built-In Regen. Resistor |

MR-RB032 [40Ω] |

MR-RB12 [40Ω] |

MR-RB30 [40Ω] |

MR-RB32 [40Ω] |

MR-RB50 [40Ω] (Note) | |

|

Stocked Item |

N/A |

S |

S |

S |

S |

S |

|

MR-E-10 |

- |

30 |

- |

- |

- |

- |

|

MR-E-20 |

- |

30 |

100 |

- |

- |

- |

|

MR-E-40 |

10 |

30 |

100 |

- |

- | |

|

MR-E-70 |

20 |

30 |

100 |

- |

300 |

- |

|

MR-E-100 |

20 |

30 |

100 |

- |

300 |

- |

|

MR-E-200 |

100 |

- |

- |

300 |

- |

500 |

Note: Always install a cooling fan when using MR-RB50.

AC Power Improving Reactor Options

|

Model Type |

Model Number |

Stocked Item |

|

MR-E-10 to 40 |

MRL-00402 |

S |

|

MR-E-70 |

MRL-00802 |

S |

|

MR-E-100 |

MRL-01202 |

S |

|

MR-E-200 |

MRL-01802 |

S |

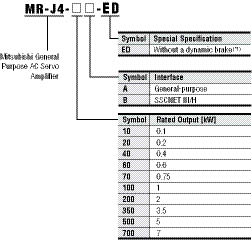

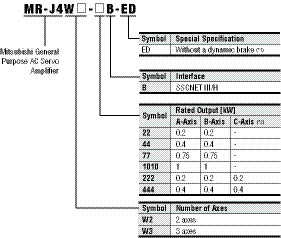

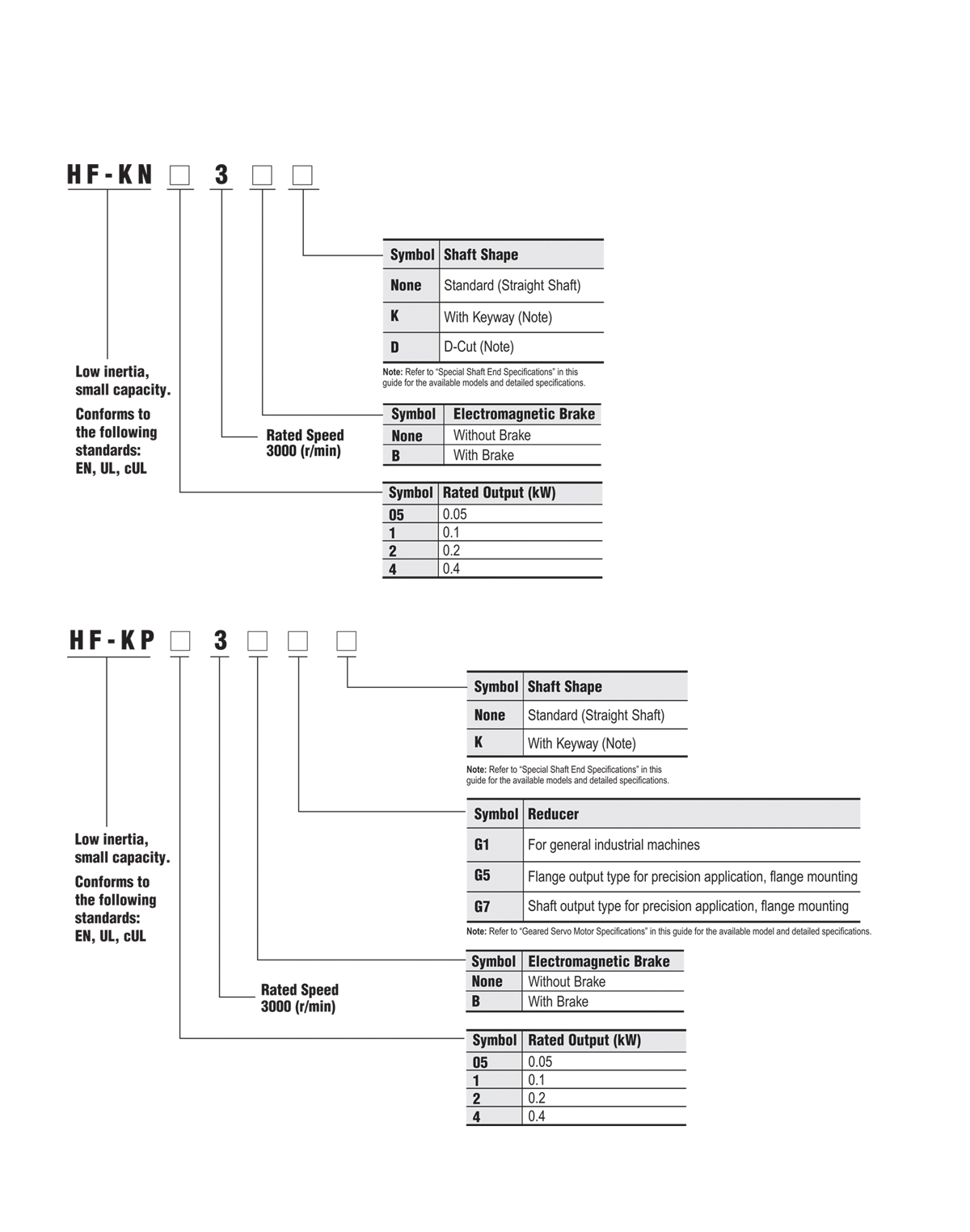

Информация MR-J4

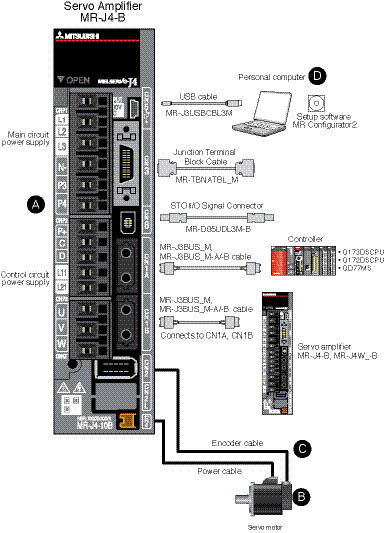

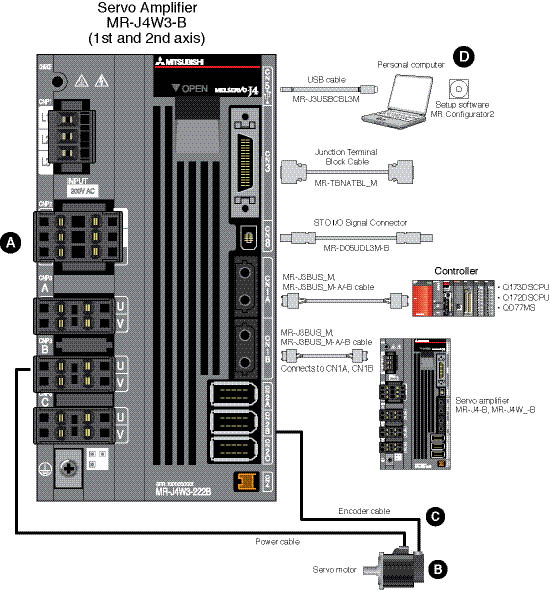

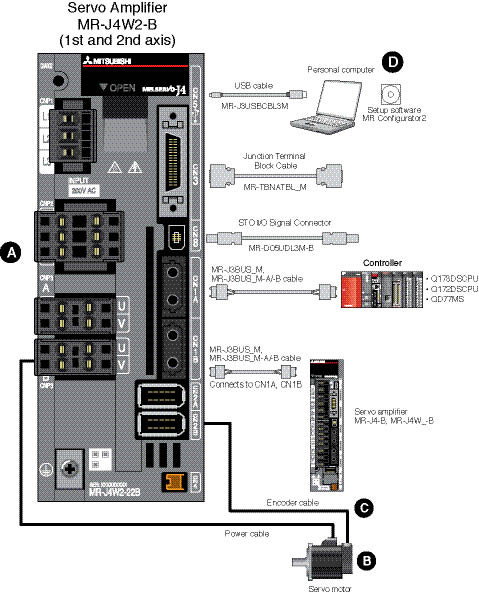

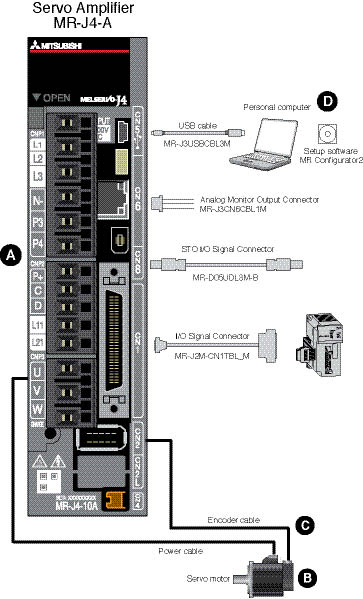

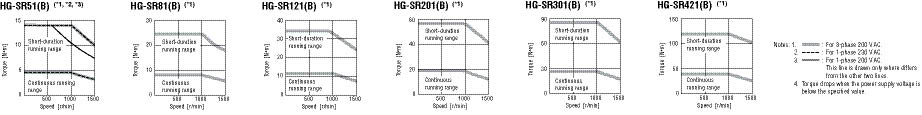

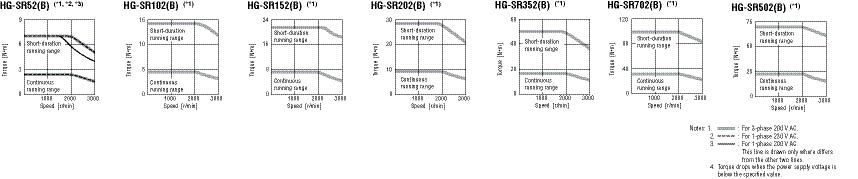

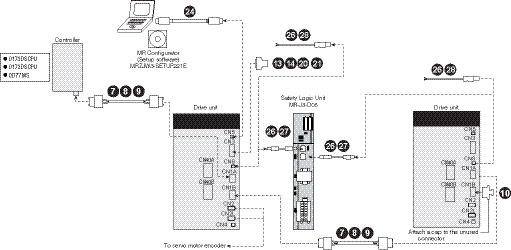

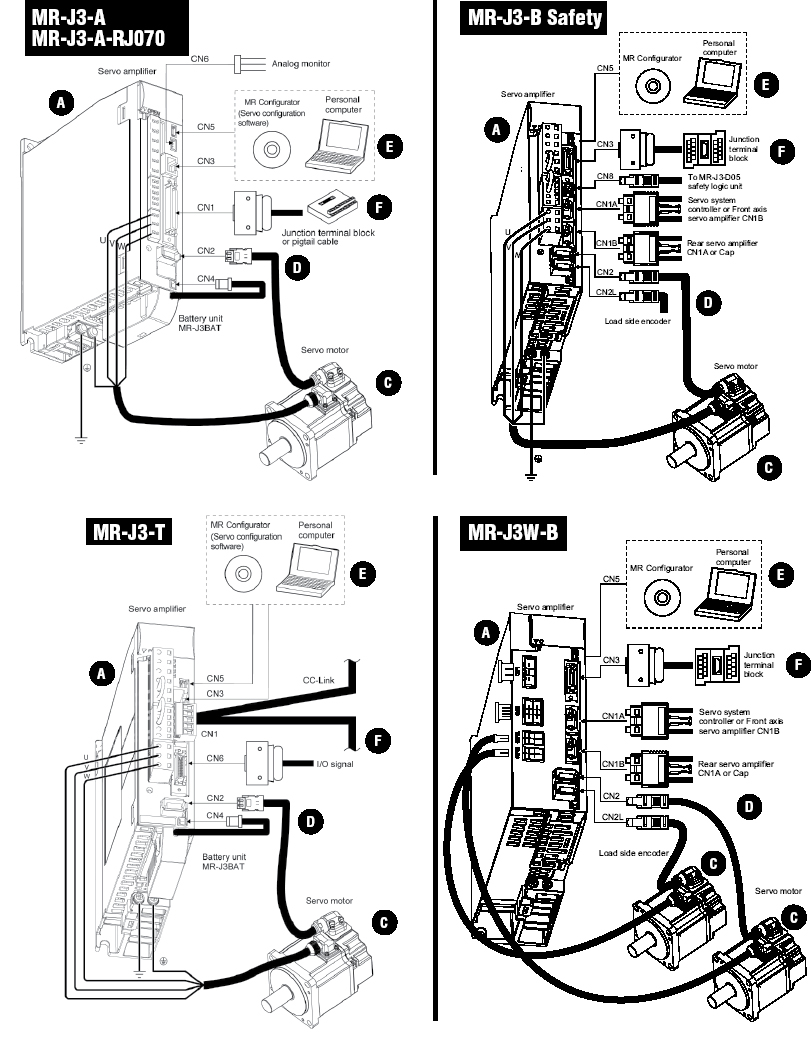

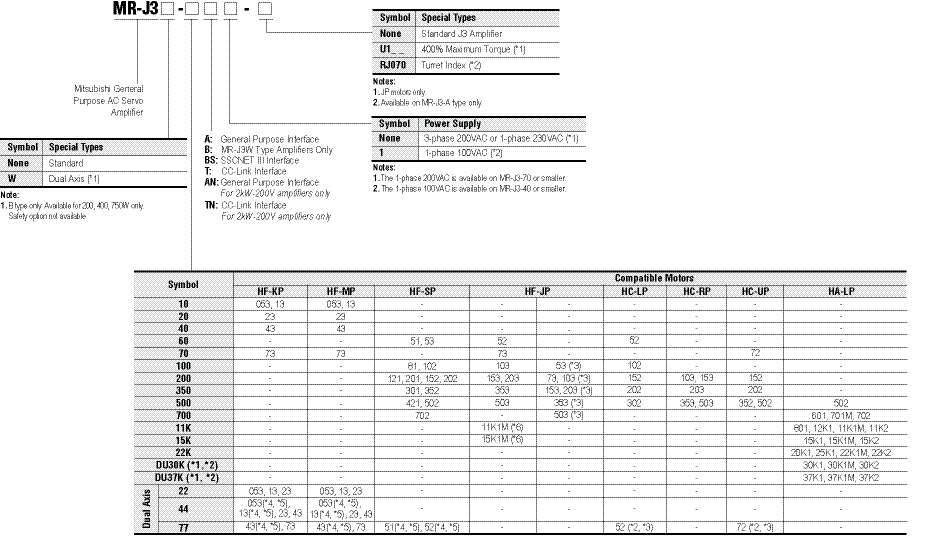

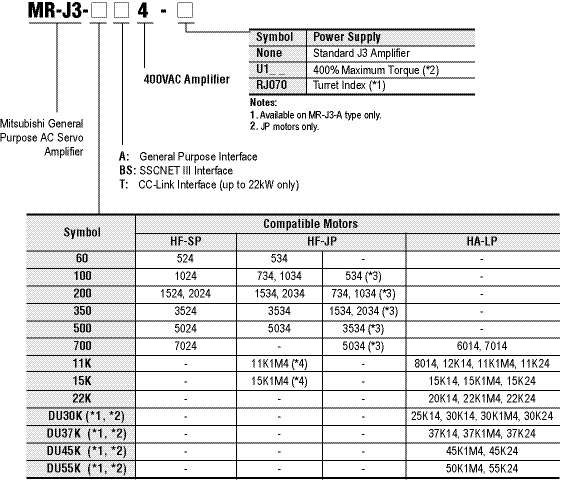

Overview and Configuration

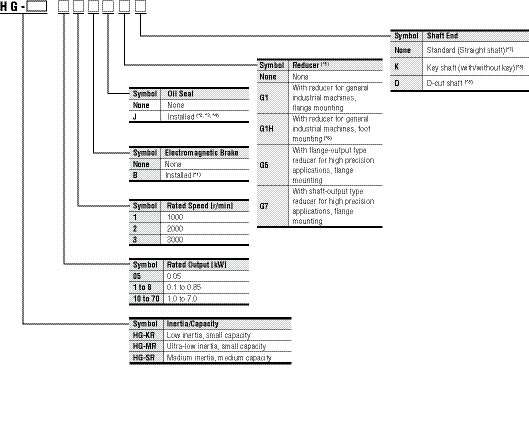

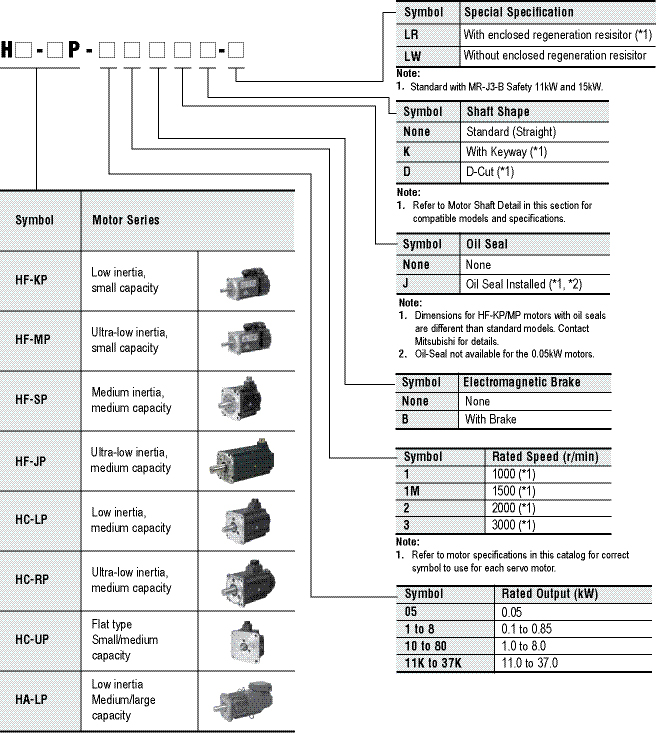

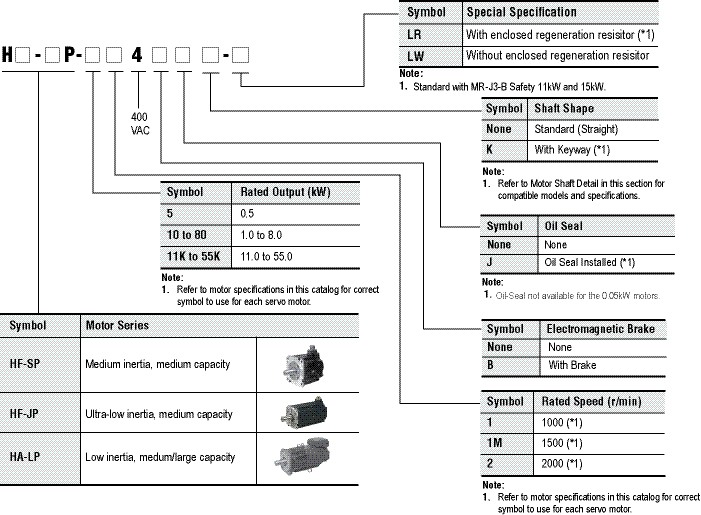

With a capacity range of 50W to 7kW (200V only), both the amplifier and motor size is reduced. We added a high resolution encoder of 4 million pulse/rev, with a speed frequency response of 2500Hz. Additional features include advanced one-touch auto tuning and advanced vibration suppression control II functions. The MR-J4 motors have the same flange size as J3 motors with the length of the motor being the same or smaller than the J3. The same cables for power, encoder and brake can be used for the MR-J3 and MR-J4. MR-J4 Series has four models: MR-J4A (analog/pulse train), MR-J4B, (SSCNET III/H), MR-J4W2B (Dual axis amplifier with SSCNET III/H) and MR-J4W3B (Three axis in one amplifier with SSCNET III/H). In addition, MR-J4 has three motor models available: HG-KR similar to HF-KP, HG-MR similar to HF-MP, and HG-SR similar to HF-SP Series. M-Size software is used to size HG Series motors and setup is made easy using MR-Configurator.

MR-J4-B

MR-J4W3-B

MR-J4W2-B

MR-J4-A

A. MR-J4 Amplifiers

B. MR-J4 Rotary Servomotors

C. Servo Amplifier Cables and Connectors

D. Software and Manuals

E. System Options

|

Rotary Servomotor Series |

Rated Speed (Max. r/min) |

Rated Output Capacity (kW) |

Servomotor Type |

Protective Degree (*2) |

Compatible Series |

Features |

Application Examples | |||

|

Electromagnetic Brake Available |

With Reducer (G1) (*1) |

With Reducer (G5, G7) (*1) | ||||||||

|

Small Capacity |

HG-KR

|

3000 (6000) |

5 Types

|

X |

X |

X |

IP65 |

HF-KP |

Low inertia: perfect for general industrial machines |

|

|

HG-MR |

3000 (6000) |

5 Types

|

X |

- |

- |

IP65 |

HF-MP |

Ultra-low inertia

Well suited for

high-throughput

operations |

| |

|

Medium Capacity |

HG-SR |

1000 (1500) |

6 Types

|

X |

- |

- |

IP67 |

HF-SP |

Medium inertia

This series is

available with two rated speeds |

|

|

2000 (3000) |

7 Types

|

X |

X |

X |

IP67 | |||||

Notes:

- G1 for general industrial machines. G5 and G7 for high precision applications.

(Example Part No. = HG-KR053BG1)

Not all options available for every motor.

Notes:

- Refer to electromagnetic brake specifications of each servomotor series in this catalog for the available models and detailed specifications.

- Available in 0.1 kW or larger HG-KR/HG-MR series and all HG-SR series.

- Oil seal is not installed in the geared servomotor.

- Dimensions for HG-KR/HG-MR/HG-SR series with an oil seal are different from the standard models. Contact your local sales office for more details.

- Available only in HF-SR 2000 r/min series.

- Standard HG-SR G1/G1H has a key shaft (with key).

- Refer to special shaft end specifications of each servomotor series in this catalog for the available models and detailed specifications.

Stocked Motors

|

Model Number | |

|

HG-KR053(B) | |

|

HG-KR13(B) | |

|

HG-KR23(B) | |

|

HG-KR43(B) | |

|

HG-KR73(B) | |

|

HG-KR053(B)D | |

|

HG-KR13(B)D | |

|

HG-KR23(B)K | |

|

HG-KR43(B)K | |

|

HG-KR73(B)K | |

|

HG-MR053(B) | |

|

HG-MR13(B) | |

|

HG-MR23(B) | |

|

HG-MR43(B) | |

|

HG-MR73(B) | |

|

HG-MR053(B)D | |

|

HG-MR13(B)D | |

|

HG-MR23(B)K | |

|

HG-MR43(B)K | |

|

HG-MR73(B)K | |

|

Model Number | |

|

HG-SR52(B) | |

|

HG-SR102(B) | |

|

HG-SR152(B) | |

|

HG-SR202(B) | |

|

HG-SR352(B) | |

|

HG-SR-502(B) | |

|

HG-SR702(B) | |

|

HG-SR52(B)K | |

|

HG-SR102(B)K | |

|

HG-SR152(B)K | |

|

HG-SR202(B)K | |

|

HG-SR502(B)K | |

|

HG-SR702(B)K | |

With MR-J4 Servo Amplifier

|

Rotary Servomotor |

Servo Amplifier | ||

|

HG-KR |

HG-MR |

HG-SR | |

|

053, 13 |

053, 13 |

- |

MR-J4-10A/B |

|

23 |

23 |

- |

MR-J4-20A/B |

|

43 |

43 |

- |

MR-J4-40A/B |

|

- |

- |

51, 52 |

MR-J4-60A/B |

|

73 |

73 |

- |

MR-J4-70A/B |

|

- |

- |

81, 102 |

MR-J4-100A/B |

|

- |

- |

121, 201, 152, 202 |

MR-J4-200A/B |

|

- |

- |

301, 352 |

MR-J4-350A/B |

|

- |

- |

421, 502 |

MR-J4-500A/B |

|

- |

- |

702 |

MR-J4-700A/B |

Notes:

- Any combination of the servomotors is available such as rotary servomotor for A-axis, and linear servomotor or direct drive motor for B-axis. Refer to "Combinations of Linear Servomotor and Servo Amplifier" and "Combinations of Direct Drive Motor and Servo Amplifier" in the MR-J4 brochure.

- Any combination of the servomotors is available such as rotary servomotor for A-axis, linear servomotor for B-axis, and direct drive motor for C-axis. Refer to "Combinations of Linear Servomotor and Servo Amplifier" and "Combinations of Direct Drive Motor and Servo Amplifier" in the MR-J4 brochure.

With MR-J4W2 Servo Amplifier

|

Rotary Servomotor |

Servo Amplifier |

Axis (*1) | ||

|

HG-KR |

HG-MR |

HG-SR | ||

|

053, 13, 23 |

053, 13, 23 |

- |

MR-J4W2-22B |

A/B |

|

053, 13, 23, 43 |

053, 13, 23, 43 |

- |

MR-J4W2-44B |

A/B |

|

43, 73 |

43, 73 |

51, 52 |

MR-J4W2-77B |

A/B |

|

43, 73 |

43, 73 |

51, 81, 52, 102 |

MR-J4W2-1010B |

A/B |

With MR-J4W3 Servo Amplifier

|

Rotary Servomotor |

Servo Amplifier |

Axis (*2) | ||

|

HG-KR |

HG-MR |

HG-SR | ||

|

053, 13, 23 |

053, 13, 23 |

- |

MR-J4W3-222B |

A/B/C |

|

053, 13, 23, 43 |

053, 13, 23, 43 |

- |

MR-J4W3-444B |

A/B/C |

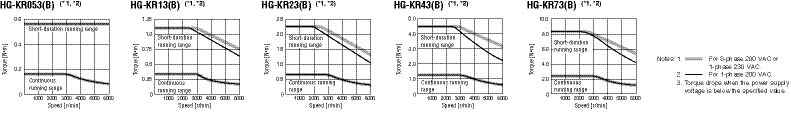

HG-KR Series (Low Inertia, Small Capacity) Specifications

|

Servomotor Model HG-KR_ |

053(B) |

13(B) |

23(B) |

43(B) |

73(B) | |

|

Servo Amplifier Model |

MR-J4-_ |

Refer to "Combinations of Servomotor and Servo Amplifier" in this guide. | ||||

|

MR-J4W_-_ | ||||||

|

Power Supply Capacity (kVA) (*1) |

0.3 |

0.3 |

0.5 |

0.9 |

1.3 | |

|

Continuous Running Duty |

Rated Output (W) |

50 |

100 |

200 |

400 |

750 |

|

Rated Torque (N•m) (*3) |

0.16 |

0.32 |

0.64 |

1.3 |

2.4 | |

|

Maximum Torque (N•m) |

0.56 |

1.1 |

2.2 |

4.5 |

8.4 | |

|

Rated Speed (r/min) |

3000 | |||||

|

Maximum Speed (r/min) |

6000 | |||||

|

Permissible Instantaneous Speed (r/min) |

6900 | |||||

|

Power Rate Continuous Rated Torque |

Standard (kW/s) |

5.63 |

13.0 |

18.3 |

43.7 |

45.2 |

|

With Electromagnetic

Brake (kW/s) |

5.37 |

12.1 |

16.7 |

41.3 |

41.6 | |

|

Rated Current (A) |

0.9 |

0.8 |

1.3 |

2.6 |

4.8 | |

|

Maximum Current (A) |

3.2 |

2.5 |

4.6 |

9.1 |

17.2 | |

|

Regenerative Braking Frequency (*2) |

MR-J4- (times/min) |

(*4) |

(*4) |

453 |

268 |

157 |

|

MR-J4W_- (times/min) |

2540 |

1370 |

451 |

268 |

393 | |

|

Moment of inertia J (x10-4kg•m²) |

Standard |

0.0450 |

0.0777 |

0.221 |

0.371 |

1.26 |

|

With Electromagnetic Brake |

0.0472 |

0.0837 |

0.243 |

0.393 |

1.37 | |

|

Recommended Load/Motor Inertia Ratio (*1) |

15 times or less |

24 times or less |

22 times or less |

15 times or less | ||

|

Speed/Position Detector |

Absolute/incremental 22-bit encoder (resolution: 4194304 pulses/rev) | |||||

|

Oil Seal |

None |

None (Servomotors with oil seal are available. (HG-KR_J)) | ||||

|

Insulation Class |

130 (B) | |||||

|

Structure |

Totally enclosed, natural cooling (IP rating: IP65) (*2) | |||||

|

Environment (*3) |

Ambient Temperature |

0°C to 40°C (non-freezing), storage: -15°C to 70°C (non-freezing) | ||||

|

Ambient Humidity |

80% RH maximum (non-condensing), storage: 90% RH maximum (non-condensing) | |||||

|

Atmosphere |

Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist or dust | |||||

|

Elevation / Vibration (*4) |

1000 m or less above sea level; X: 49 m/s² Y: 49 m/s² | |||||

|

Vibration Rank |

V10 (*6) | |||||

|

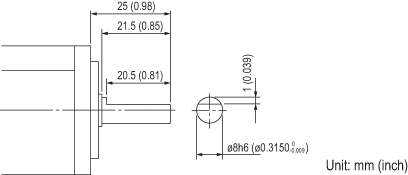

Permissible

Load for the

Shaft (*5) |

L (mm) |

25 |

25 |

30 |

30 |

40 |

|

Radial (N) |

88 |

88 |

245 |

245 |

392 | |

|

Thrust (N) |

59 |

59 |

98 |

98 |

147 | |

|

Weight kg |

Standard |

0.34 |

0.54 |

0.91 |

1.4 |

2.8 |

|

With Electromagnetic Brake |

0.54 |

0.74 |

1.3 |

1.8 |

3.8 | |

Notes:

- Contact your local sales office if the load to motor inertia ratio exceeds the value in the table.

- The shaft-through portion is excluded. IP67 for the servomotor with oil seal. Equivalent to IP44 for the reducer portion on the geared servomotor. Refer to this guide for the shaft-through portion.

- When unbalanced torque is generated, such as in a vertical lift machine, it is recommended that the unbalanced torque of the machine be kept under 70% of the servomotor rated torque.

- When the servomotor decelerates to a stop from the rated speed, the regenerative frequency will not be limited if the effective torque is within the rated torque range.

When the servomotor decelerates to a stop from the maximum speed, the regenerative frequency will not be limited if the following requirements are met.

• HG-KR053(B): The load to motor inertia ratio is 8 times or less, and the effective torque is within the rated torque range.

• HG-KR13(B): The load to motor inertia ratio is 4 times or less, and the effective torque is within the rated torque range. - The vibration direction is shown in the diagram below. The numeric value indicates the maximum value of the component (commonly the bracket in the opposite direction of the motor shaft). Fretting of the bearing occurs easily when the motor stops, so maintain vibration to approximately one-half of the allowable value.

- Refer to the MR-J4 Servo Amplifier and Motors brochure for more detailed specifications.

HG-KR Series Electromagnetic Brake Specifications (*1)

|

Servomotor Model HG-KR_ |

053B |

13B |

23B |

43B |

73B | |

|

Type |

Spring actuated type safety brake | |||||

|

Rated Voltage |

24 VDC | |||||

|

Power Consumption (W) at 20 °C |

6.3 |

6.3 |

7.9 |

7.9 |

10 | |

|

Electromagnetic Brake Static Friction Torque (N•m) |

0.32 |

0.32 |

1.3 |

1.3 |

2.4 | |

|

Permissible Braking Work |

Per Braking (J) |

5.6 |

5.6 |

22 |

22 |

64 |

|

Per Hour (J) |

56 |

56 |

220 |

220 |

640 | |

|

Electromagnetic Brake Life (*2) |

Number of Times (Times) |

20000 | ||||

|

Work Per Braking (J) |

5.6 |

5.6 |

22 |

22 |

64 | |

Notes:

- The electromagnetic brake is for holding. It should not be used for deceleration applications.

- Brake gap is not adjustable. Electromagnetic brake life is defined as the time period until the readjustment is needed.

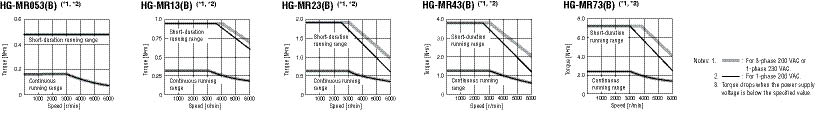

HG-MR Series (Ultra Low Inertia, Small Capacity) Specifications

|

Servomotor Model HG-MR_ |

053(B) |

13(B) |

23(B) |

43(B) |

73(B) | |

|

Servo Amplifier Model |

MR-J4-_ |

Refer to "Combinations of Servomotor and Servo Amplifier" in this guide. | ||||

|

MR-J4W_-_ | ||||||

|

Power Supply Capacity (kVA) (*1) |

0.3 |

0.3 |

0.5 |

0.9 |

1.3 | |

|

Continuous Running Duty |

Rated Output (W) |

50 |

100 |

200 |

400 |

750 |

|

Rated Torque (N•m) (*3) |

0.16 |

0.32 |

0.64 |

1.3 |

2.4 | |

|

Maximum Torque (N•m) |

0.48 |

0.95 |

1.9 |

3.8 |

7.2 | |

|

Rated Speed (r/min) |

3000 | |||||

|

Maximum Speed (r/min) |

6000 | |||||

|

Permissible Instantaneous Speed (r/min) |

6900 | |||||

|

Power Rate Continuous Rated Torque |

Standard (kW/s) |

15.6 |

33.8 |

46.9 |

114.2 |

97.3 |

|

With Electromagnetic

Brake (kW/s) |

11.3 |

28.0 |

37.2 |

98.8 |

82.1 | |

|

Rated Current (A) |

1.0 |

0.9 |

1.5 |

2.6 |

5.8 | |

|

Maximum Current (A) |

3.1 |

2.5 |

5.3 |

9.0 |

20.0 | |

|

Regenerative Braking Frequency (*2) |

MR-J4- (times/min) |

(*4) |

(*4) |

1180 |

713 |

338 |

|

MR-J4W_- (times/min) |

7540 |

3640 |

1170 |

710 |

846 | |

|

Moment of Inertia J (x10-4kg•m²) |

Standard |

0.0162 |

0.0300 |

0.0865 |

0.142 |

0.586 |

|

With Electromagnetic Brake |

0.0224 |

0.0362 |

0.109 |

0.164 |

0.694 | |

|

Recommended Load/Motor Inertia Ratio (*1) |

30 times or less | |||||

|

Speed/Position Detector |

Absolute/incremental 22-bit encoder (resolution: 4194304 pulses/rev) | |||||

|

Oil Seal |

None |

None (Servomotors with oil seal are available. (HG-MR_J)) | ||||

|

Insulation Class |

130 (B) | |||||

|

Structure |

Totally enclosed, natural cooling (IP rating: IP65) (*2) | |||||

|

Environment (*3) |

Ambient Temperature |

0°C to 40°C (non-freezing), storage: -15°C to 70°C (non-freezing) | ||||

|

Ambient Humidity |

80% RH maximum (non-condensing), storage: 90% RH maximum (non-condensing) | |||||

|

Atmosphere |

Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist or dust | |||||

|

Elevation / Vibration (*4) |

1000 m or less above sea level; X: 49 m/s² Y: 49 m/s² | |||||

|

Vibration Rank |

V10 (*6) | |||||

|

Permissible Load for the Shaft (*5) |

L (mm) |

25 |

25 |

30 |

30 |

40 |

|

Radial (N) |

88 |

88 |

245 |

245 |

392 | |

|

Thrust (N) |

59 |

59 |

98 |

98 |

147 | |

|

Weight kg |

Standard |

0.34 |

0.54 |

0.91 |

1.4 |

2.8 |

|

With Electromagnetic Brake |

0.54 |

0.74 |

1.3 |

1.8 |

3.8 | |

Notes:

- Contact your local sales office if the load to motor inertia ratio exceeds the value in the table.

- The shaft-through portion is excluded. IP67 for the servomotor with oil seal. Refer to the asterisk 7 of "Annotations for Rotary Servomotor Specifications" on p. 2-13 in this catalog for the shaft-through portion.

- When unbalanced torque is generated, such as in a vertical lift machine, it is recommended that the unbalanced torque of the machine be kept under 70% of the servomotor rated torque.

- When the servomotor decelerates to a stop from the rated speed, the regenerative frequency will not be limited if the effective torque is within the rated torque range.

When the servomotor decelerates to a stop from the maximum speed, the regenerative frequency will not be limited if the following requirements are met.

• HG-MR053(B): The load to motor inertia ratio is 24 times or less, and the effective torque is within the rated torque range.

• HG-MR13(B): The load to motor inertia ratio is 12 times or less, and the effective torque is within the rated torque range. - The vibration direction is shown in the diagram below. The numeric value indicates the maximum value of the component (commonly the bracket in the opposite direction of the motor shaft). Fretting of the bearing occurs easily when the motor stops, so maintain vibration to approximately one-half of the allowable value.

- Refer to the MR-J4 Servo Amplifier and Motors brochure for more detailed specifications.

HG-MR Series Electromagnetic Brake Specifications (*1)

|

Servomotor Model HG-MR_ |

053B |

13B |

23B |

43B |

73B | |

|

Type |

Spring actuated type safety brake | |||||

|

Rated Voltage |

24 VDC | |||||

|

Power Consumption (W) at 20°C |

6.3 |

6.3 |

7.9 |

7.9 |

10 | |

|

Electromagnetic Brake Static Friction Torque (N•m) |

0.32 |

0.32 |

1.3 |

1.3 |

2.4 | |

|

Permissible Braking Work |

Per Braking (J) |

5.6 |

5.6 |

22 |

22 |

64 |

|

Per Hour (J) |

56 |

56 |

220 |

220 |

640 | |

|

Electromagnetic Brake Life (*2) |

Number of Times (Times) |

20000 | ||||

|

Work Per Braking (J) |

5.6 |

5.6 |

22 |

22 |

64 | |

- The electromagnetic brake is for holding. It should not be used for deceleration applications.

- Brake gap is not adjustable. Electromagnetic brake life is defined as the time period until the readjustment is needed.

|

Servomotor Model HG-SR_ |

51(B) |

81(B) |

121(B) |

201(B) |

301(B) |

421(B) | |

|

Servo Amplifier Model |

MR-J4-_ |

Refer to "Combinations of Servomotor and Servo Amplifier" in this guide. | |||||

|

MR-J4W_-_ | |||||||

|

Power Supply Capacity (kVA) (*1) |

1.0 |

1.5 |

2.1 |

3.5 |

4.8 |

6.3 | |

|

Continuous Running Duty |

Rated Output (kW) |

0.5 |

0.85 |

1.2 |

2.0 |

3.0 |

4.2 |

|

Rated Torque (N•m) (*3) |

4.8 |

8.1 |

11.5 |

19.1 |

28.6 |

40.1 | |

|

Maximum Torque (N•m) |

14.3 |

24.4 |

34.4 |

57.3 |

85.9 |

120 | |

|

Rated Speed (r/min) |

1000 | ||||||

|

Maximum Speed (r/min) |

1500 | ||||||

|

Permissible Instantaneous Speed (r/min) |

1725 | ||||||

|

Power Rate Continuous Rated Torque |

Standard (kW/s) |

19.7 |

41.2 |

28.1 |

46.4 |

82.3 |

107 |

|

With Electromagnetic

Brake (kW/s) |

16.5 |

36.2 |

23.2 |

41.4 |

75.3 |

99.9 | |

|

Rated Current (A) |

2.8 |

5.2 |

7.1 |

9.4 |

13 |

19 | |

|

Maximum Current (A) |

9.0 |

16.6 |

22.7 |

30.1 |

41.6 |

60.8 | |

|

Regenerative Braking Frequency (*2) |

MR-J4- (times/min) |

77 |

114 |

191 |

113 |

89 |

76 |

|

MR-J4W_- (times/min) |

392 |

286 |

- |

- |

- |

- | |

|

Moment of Inertia J (x10-4kg•m²) |

Standard |

11.6 |

16.0 |

46.8 |

78.6 |

99.7 |

151 |

|

With Electromagnetic Brake |

13.8 |

18.2 |

56.5 |

88.2 |

109 |

161 | |

|

Recommended Load/Motor Inertia Ratio (*1) |

15 times or less | ||||||

|

Speed/Position Detector |

Absolute/incremental 22-bit encoder (resolution: 4194304 pulses/rev) | ||||||

|

Oil Seal |

None (Servomotors with oil seal are available. (HG-SR_J)) | ||||||

|

Insulation Class |

155 (F) | ||||||

|

Structure |

Totally enclosed, natural cooling (IP rating: IP67) (*2) | ||||||

|

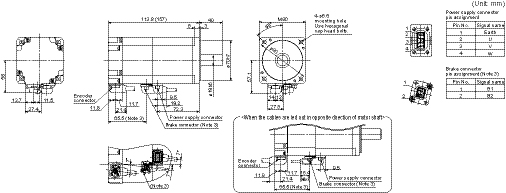

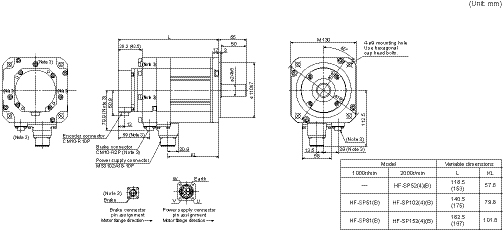

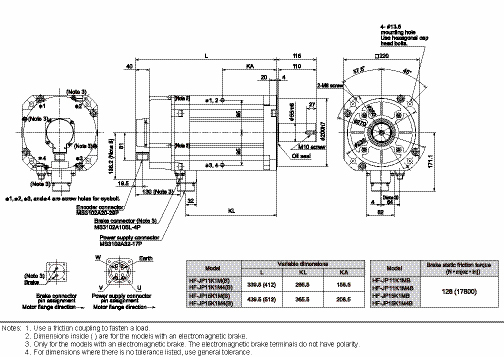

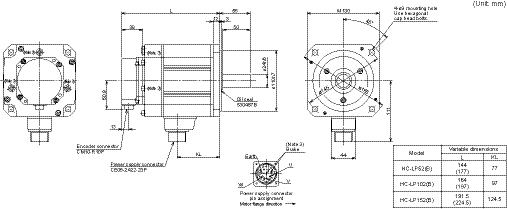

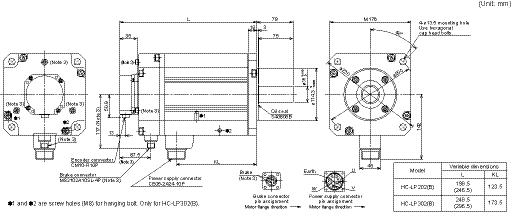

Environment (*3) |